So we are in no doubt lets review what needs to be done to remove the MOSFet ‘resistor’ block.

Fitted in position the space between the bulkhead and the plug-in connector of the loom is approx. 2 inches, just enough to get extended fingers up to feel, if you have small hands. You cannot manipulate the plug and you cannot get a stubby screwdriver up and onto the two screws holding the MOSFet block in place. Been there tried that!

Workspace to do this job required each door to be fully opened or openable ‘fully’ at some stage of the process. If that means moving the car out the garage to do it, be prepared.

Removal of dash.

Under the bonnet disconnect A/C and coolant pipes going through bulkhead in front of passenger.

Strip out the hood guides and the head lining plastic trim enough to allow the A pillar trim to be removed.

Passenger side

Strip out seats(Its just a lot easier if you do), door opening plastic including the rubber seal and trim from ‘A’ pillar.

Strip out glove box, peel back passenger carpet as far as you can, remove passenger foot rest.

Remove heated seat panel and console side trims.

To lighten the dash assembly you can remove audio, speedo and trim but its not essential.

Drivers side

Remove all, under steering wheel trim including the steering column plastic.

Detach the bonnet release mech from lower dash.

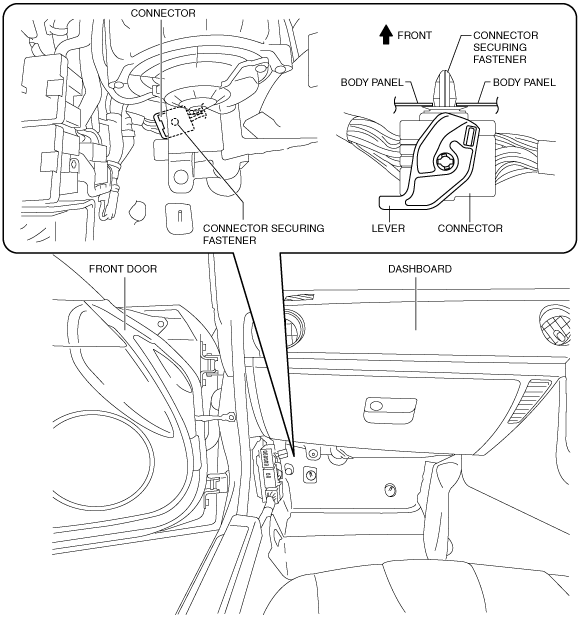

Remove all loom connectors including the big white connector behind the speedo area but accessed from the drivers foot well.

There is a yellow air bag connector there too that needs disconnecting.

Disconnect all the loom connections to the steering column switches.

There is an aerial connector rising from the drivers footwell up the ‘A’ pillar and across into the dash.

Lower steering wheel and column to the floor.

There is a big blue connector in the passenger side foot well behind the heater support stalk and you need to move the dashboard out by inches before you can disconnect it so prep the apprentice.

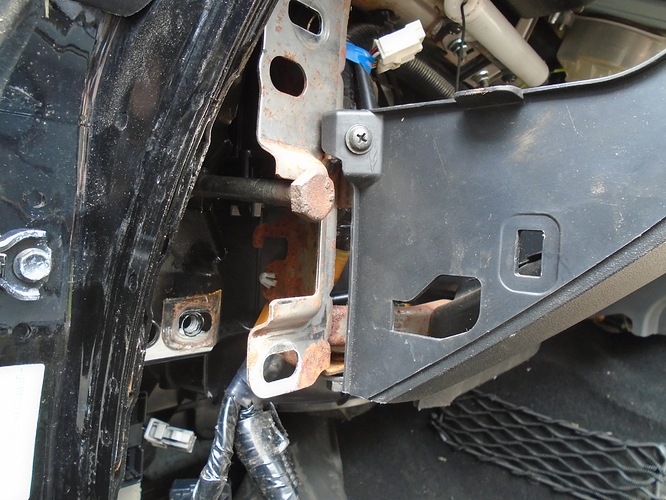

There are 14 bolts holding the dashboard in place, open both door fully, in the upper rear of the wing remove the rubber domes and remove the bolt it covers (its a long bolt) below that one there is a second shorter bolt, both sides. Passenger foot well heater support stalk one bolt. On either side on ctr console two bolts on each side. Steering column support there is a final bolt in the middle of the column retainer, high up under the speedo area…

Four bolts to go.

On each side on the ‘A’ pillar there are 2 bolts that face towards you at the lip of the door to dash

Fit 4" bolts to the middle hole of the mounting bracket that is fixed to the chassis. When the dash is moved forwards it can rest on these bolts and not fall into the car.

Ease the dash forwards and check you got all the loom connectors, there is always one more!

Column down and dash 4" forward resting on bolt shown more closely on second picture…

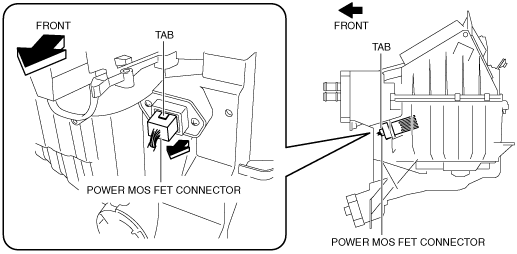

OK now you have access to the ‘behind heater area’ you can remove the MOSFet controller.

If you disconnect the passenger side footwell blue connector… you can lift the dashboard right out the car and work on the floor.

This is the abridged version of a 6 page multi picture account of this job. (too big for a post)

If you asked me to do it on your car I would ask £900 also.

With a nod to Haynes ‘Replacement is the reverse of the removal procedure’.

My original objective was to remove the MOSFet heatsink and replace the MOSFet chip and refit which I did, the MOSFet chip cost £3 for 2off.

The replacement of the chip took about 10 minutes.

Regrettably the heater blower is an essential part of the capability to de-mist the screen so it has to be done.

I hope you enjoyed reading this journey, it was fun once completed.

On a side note electronic ‘resistors’ get hot also not just resistive load controllers. The MOSFet can control 15amps and dissipates a large amount of heat in the process hence the extended heatsink into the blower air flow. Order of magnitude that’s 150watts of power, try holding a 100 watt incandescent bulb for more than a second, or a headlight bulb.