- My model of MX-5 is: __NC 2006

- I’m based near: __ NE Derbyshire

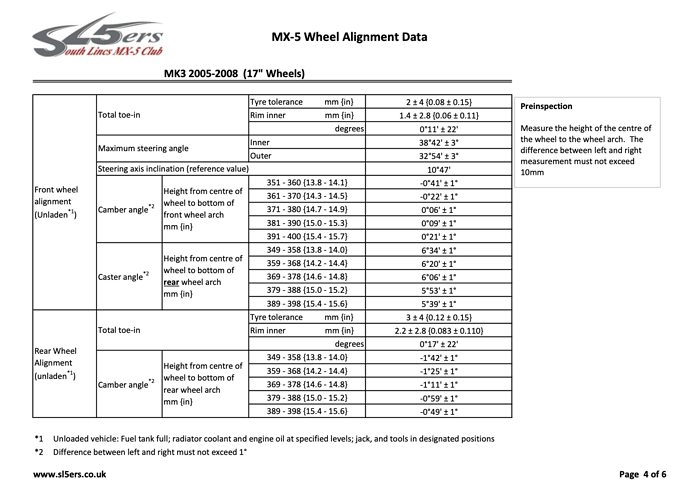

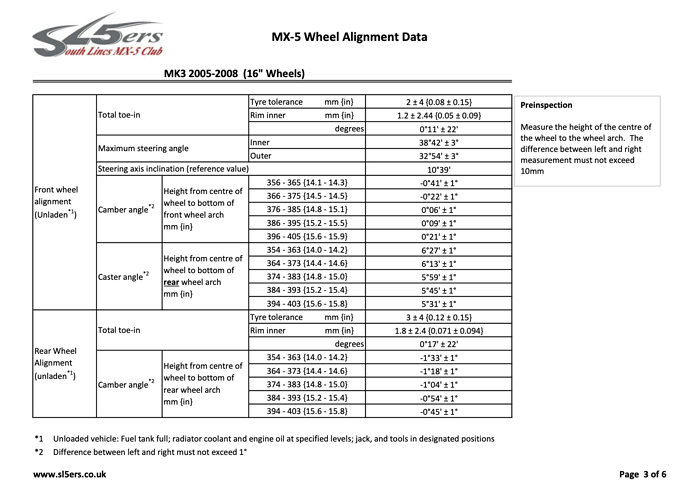

- I’m looking for technical help or recommendations on: __ Wheel alignment, I have been told the standard (i.e. Factory) road set up for a 2006 NC is the same as NA & NB please can anyone advise if this is correct? Soz if this has been ask before but never asked anything before. Thanks in advance

Looking at this article, I’d say yes…

I’m no expert though…

If you can find a tyre fitting company that uses a ‘Hunter’ wheel alignment system they will have the latest settings for your car. Apparently Hunter get wheel alignment info and updates direct from Mazda I was told.

Whatever you do the Hunter is the way to go, just about as good as it gets in my view.

I was given a printout of the settings before and then after setup, Brill!!!

Roy

PS … I think the info you seek is in the Downloads section of the Owners Club.

Roy

Thanks so much especially for the quick response!! Roy very helpful

Thanks

Thanks

What’s the relevance of “rim inner”? Aren’t all toe measurements routinely taken from the outside of the wheel rims? Furthermore what does a “rim inner” measurement of 1.4 + or - 2.8mm actually mean in practice? Is it saying it’s ok to set total from toe anywhere from toe out of 1.4mm to total toe in of 4.2mm?

Not an alignment specialist so I have no idea what the relevance of “rim inner” is.

When I get my alignment checked and adjusted I am happy to understand what the Camber, Total toe-in and in the case off the front wheels what the caster should be.

My main concern is to get things as close to road driving target setting and even both sides.

Alignment should be done with full tank, car unloaded, tyre pressures set and tools in their place.

The wheel heights should be within 10mm difference each side.

The problem I have had with wheel height is finding level ground to measure the heights. Usually I find that although left and right heights may be within the 10mm tolerance one side can be in one height range and the other in a different one. Leaves a decision as to exactly what the target settings should be!

But aside from what “inner rim” actually relates to, the main point of what I’m questioning is how much tolerance is supposedly acceptable. You’re quite right to want setting values to be the same each side, but a tolerance of plus/minus 2.5mm on toe and plus/minus 1 deg on camber can make a huge difference to the way a car will drive on the road (or track).

The point about side to side ride height differences giving different camber target values is essentially down to the way the suspension geometry works (ie when going up and down relative its position at rest), but my first priority would be asking why there might be any difference at all (eg because a spring is starting to fail, or might even be broken, worn bushes etc).

Those look like a copy paste of the settings that I did for the Downloads section.

Rim Inner is if you’re measuring in mm, the the difference in distance between the inside of the wheel rim between the leading edge and trailing edge measured at the 3 & 9 o’clock positions. The leading edge of the rims are 1.4mm closer together than the trailing edge. If you’re working in degrees then the mom measurement is irrelevant.

Agreed, but what do you make of the tolerances aspect? When I ask for front total toe of 1mm, or 2mm or whatever, I want and expect it to be spot on. Although I do accept that even a small amount of wheel rim runout could give rise to spurious accuracy.

Mazda offer a tolerance, but yes, if I were setting the alignment I’d set it to the centre of the tolerance, 1.4mm in this case. Wheel alignment depends heavily on the operator of the equipment. Lengths of wire and spirit levels can give just as accurate results as a multi thousand pound alignment machine if the wrong person is operating it.

Got it.

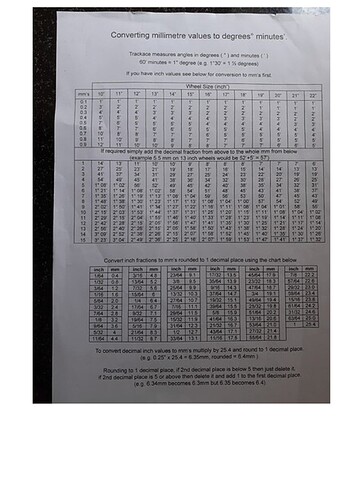

Aways ignored the “rim inner” since I always considered degrees & arc minutes.

I thought that the alignment gear (Hunter or otherwise) measured from the outer rim rather that the outer.

Anyway the link below gives mm converted to degrees and the 1.4mm is 11 arc minutes with 2.8mm tolerance being 22 arc minutes.

Tolerances are are not an issue if you aim closely for the target setting.

You can be within tolerances and have one axle wheel negative camber and the other positive or toe out instead of toe in.

It is possible the car can leave the factory in this silly position.

The retail garage does not (as far as I know) check wheel alignment before handing the new car over.

Probably best to get a newly obtained mx5 set up by someone with the right equipment and who knows what they are doing.

Would you routinely measure wheel rim runout before starting an alignment?

Some machines offer that option.