Ive had the rear of my mk1 in the air on the drive a lot just lately, im fortunate enough the sills are solid enough that i can lift her high enough to get the trolley jack (not a low profile type) under the rear end of the floor rails then i put the axle stands (after removing the wheels) into the arch of the chassis rail, this means the axle stands are at they’re full height. I would prefer to put them where i jack up with the trolley jack so i could get the rear a little higher.

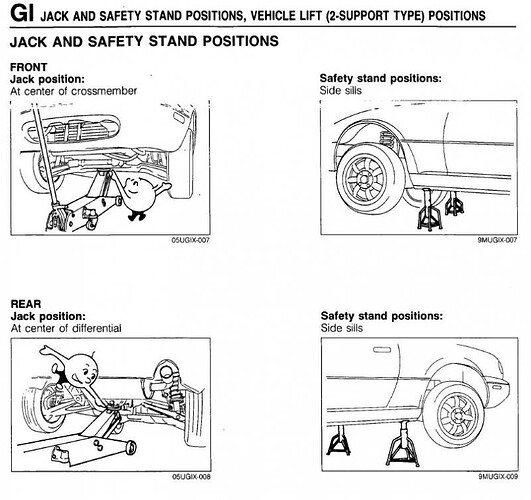

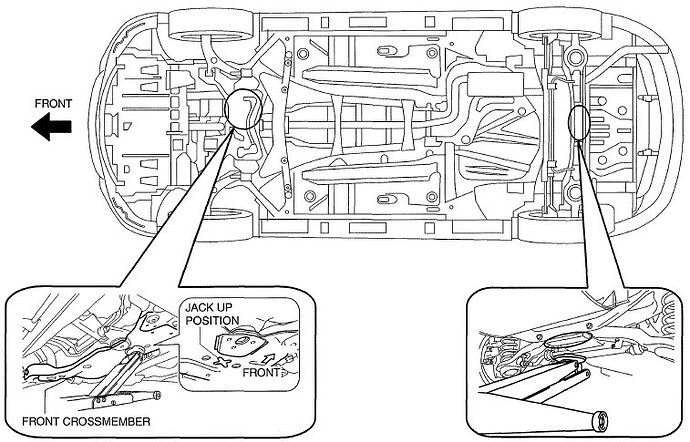

I understand some use the diff to jack up on this would allow me to put the stands under the rails but concerned about damaging the casting, what about putting the stands at the rear most part of the chassis legs near the tow eyes?

Suggestions welcome, are there other places i could use the trolley jack at the rear?

Some say don’t jack on the diff as it could crack the mounting points. I’ve been doing it for a number of years on NA/NB/NC models with no problems. TBH I try not to jack on there now but I find it easier to jack elsewhere now one jack is low profile.

Put an offcut of timber between jack head and diff casing if jacking there…

I run my NC up ramps ( they have extensions for low ride height vehicles ) and then insert the axle stands.

From your photo that’s pretty much what I want to do under the diff, might buy the davefab rear jacking brace at some point in the future to ease my concerns, thanks

Jack up on the diff at the rear and the sub frame at the front to work on, as for the axle stands that all depends on the condition of the roadster for placement to be safe to work on, if you start to lower down and you hear corn flakes, its not the correct place.

M-m

Thanks

DO NOT drop her onto the axle stands on the sill lip, the resting point is “behind” the lip all depending on the condition of the roadster or what area you are working on.

M-m

Seriously, how stupid do you think I am?

I would not drop it on the sill lip unless supported each side of the sill😳

Going under a car terrifies me sufficiently that I jack it up, in stages if necessary, and put a pile of big paving blocks under the tyres. It isn’t going to slip or fall off those.

The oil filter on an NC is super-inaccessible, being about a third of the way down the car and in the middle. It’s probably easy on a Focus!

Chill I was going off the diagram, and do not support on the outer sill either or at the same time, its not designed to be strong enough.

M-m

OK , for the OP that asked the question, you need to have a good jack and stands, some small stands can be dangerous to use, so pick and spend well on the correct tools for the job, cutting corners and one landing on you is not good, you need to assess the car on condition to where best the car is to be supported , if the jacking points" behind the sill lip" is good ,then she rests on them, this also depends on the job thats being done, if you are welding new sill sections in etc, then a better place thats safe needs to be found and for the safe height to work at or under, always try to get them onto to 4 corners for best support , resting on the

under body floor pan chassis rails is no the best of places for axle stands for one to be safe to get under neither is uneven or a slope,flat solid ground is a no brainer, some of our axle stands will go to 2.5 ’ as will the jack and all rock solid, safe as houses, but that is the height we need to do the projects/builds/ restorations/revamps etc we do with some jobs, brakes and what nots will be rested on smaller stands, …

M-m