Hi all,

Wanted to share with you, how chuffed i am with my recent DIY install of the BBR stage II turbo kit on my NC.

I’ve benefited greatly from this forum and the club, so i hope you find this useful.

I could make the man maths work, I used some bribery techniques to get what I wanted, so I took the plunge.

I did consider some alternative options, both from BBR GTI and others, but decided that modifications that focused on normally aspirated methods were not what I wanted for a road car. The torque of the turbo was what I wanted.

Before the arrival of the kit, i prepared and started to disassemble my car.

I’m reasonably close to BBR, so i collected my kit.

Everything was labeled and well wrapped.

As a stage II, the kit included a new clutch and a complete exhaust.

The main turbo and oil lines were pre assembled, only requiring installation of the downpipe.

A sandwich plate for the oil filter housing is included for the oil supply. The sump requires drilling and tapping as well.

The complete assembly.

Installed in the car.

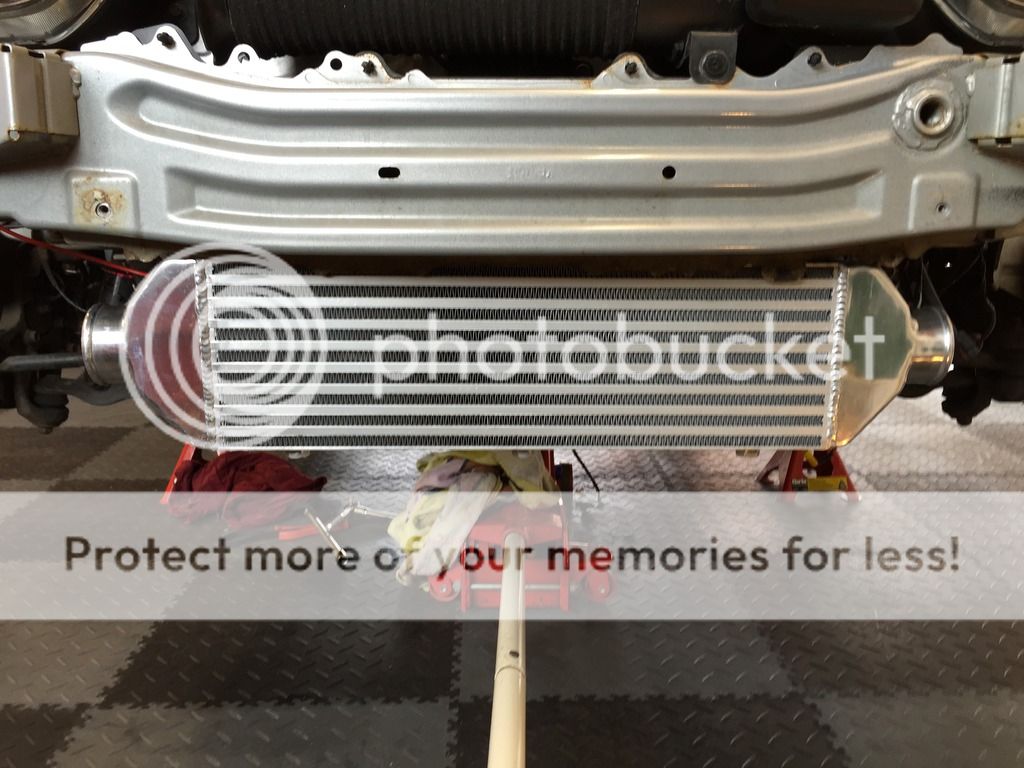

The intercooler, nice and shiny.

The new clutch.

There are a few coolant pipes to re-route and install some new ones, a single wire to cut and solder, a number of intake pipes to install, new injectors etc.

Here you can see the new injectors on the left, the old on the right.

While checking for coolant leaks after the install, i kind of wish i could have driven it around without the front bumper on

The first map and logging was done via the ODBII port.

As you can see, it’s a very neat install.

Impressions?

It’s a giggle, it really is. The noise is lovely, the rear silencer is certainly loud when you are on it, but does quiet down when cruising.

The clutch is not appreciably heavier than standard, if there is any difference in peddle weight, i can’t detect it.

The ease with which it picks up speed is hilarious, without trying, without going anywhere near the read line, it wafts along just fine.

Traction control is not unduly bothered, i can make it work for it’s tea, but my tyres are doing a fine job of dealing with the torque. (maxxis Victra MAz1)

I’m beginning to think my coilovers could perhaps do with a bit more travel, or maybe i should just slow down a little, not sure yet.

I can’t recommend it enough, was great fun installing it, even more fun driving it. The support from BBR during the install was excellent.

I hope you find my comments and photos useful.