I’ve been probing around for a while, planning a for something a bit ‘unconventional’ next for my ND. (probably more common on earlier models…?)

having had some ‘test’ runs with the OEM underbracing off, and the front strut off and seeing/feeling the difference i have had an eye / plan to fully stiffen the underbody.

thats part 1…

secondly the single best driving improvement for me was fitting the flat floor which really helped stabilise the rear at high speed corners. so functional aero under there has solid functional use

thats part 2.

so, how do i do both? (and do them both better?)

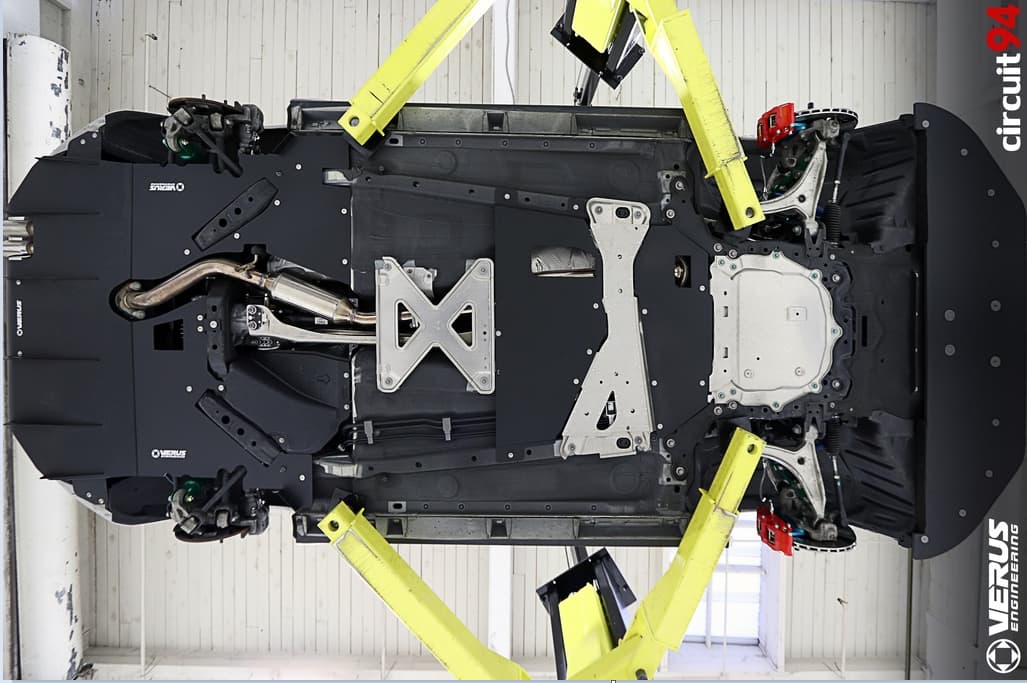

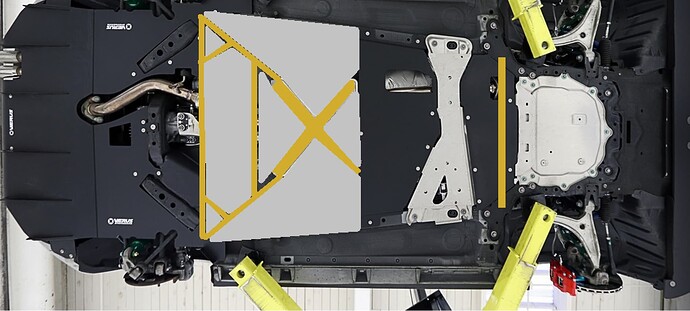

Below is a sample pic of how my ND looks from below, as i have the full Verus kit fitted. I dont have an angled view from the front, but i can tell you now - it may be ‘flat’, but its far from smooth or uniform.

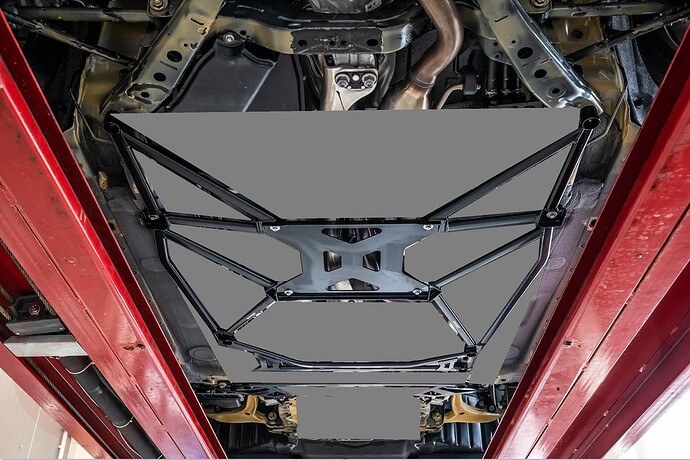

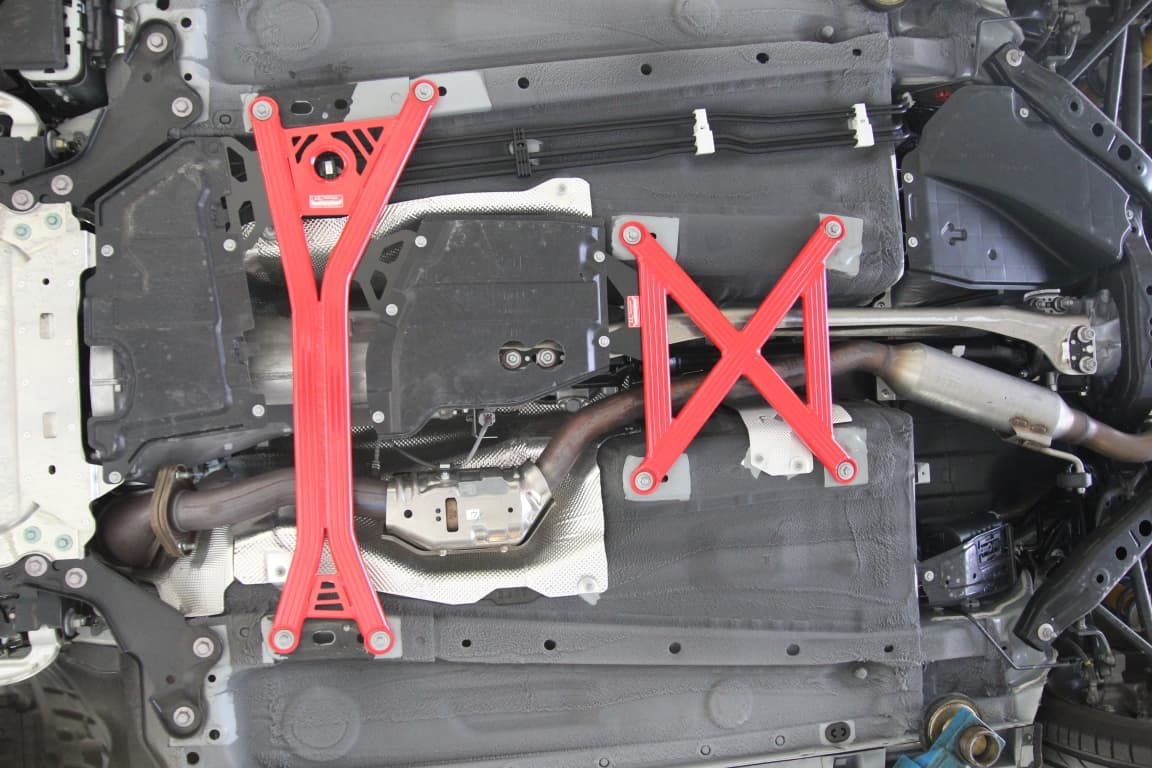

What i would like to do, is to custom fabricate a fully flat sheet(s) to make a flat floor like a typical sports marque may do. example below).

of course… i have some ventilation to think so, so understand my example are just a guide not a final product.

Fabricating this and fixing will be, to be honest, easy. theres a choice of materials. dozens of mounting points. and its fully function not fashion - so doesnt matter how it looks.

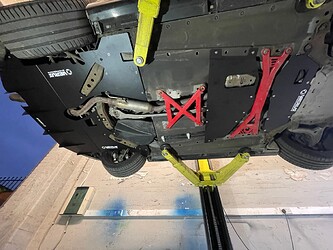

But, lets factor in those braces again…

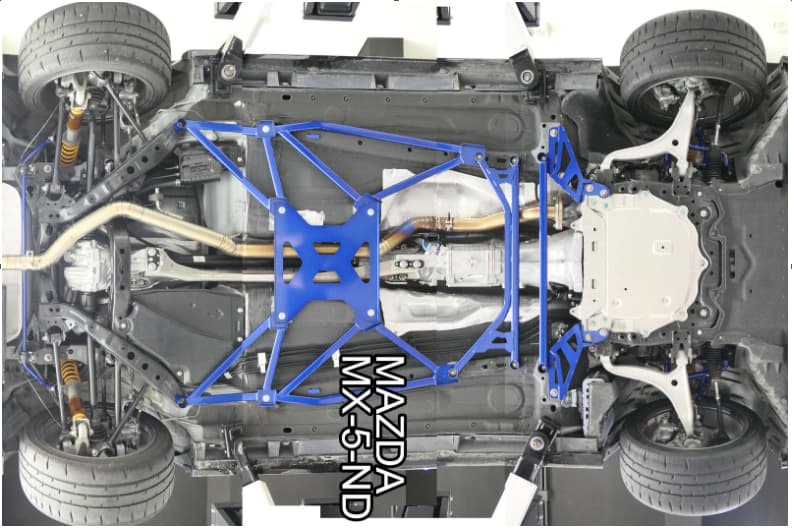

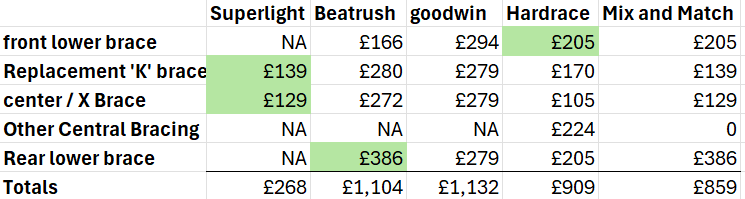

I have been looking at either the goodwin aluminium set, or the Hardrace. (both about the same price). in terms of benefit gained i image both will be of similar improvement. the goodwin may be lighter (and not bloody blue!) BUT, i cant weld to aluminium. which might be a requirement…

The conundrum i have at the moment is as follows, and i think i have 3 options:

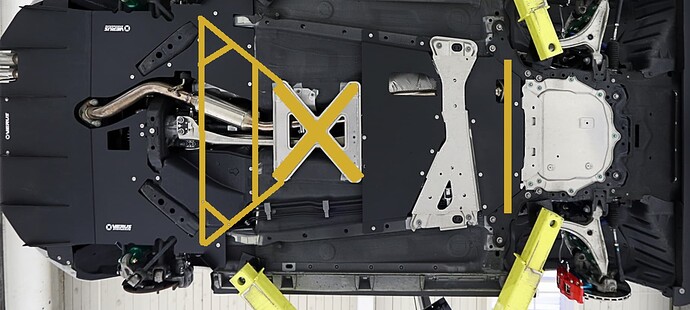

a) The bracing kits are not a uniform height on the ground side. meaning, applying a flat-floor on the ground side will require alot of spacers in other areas and massively reduce ground clearance, while also creating an airflow issue with closing gaps on the front and sides so not to create a sort of wing under there. this is due to the mounting points having immense skirts for the bolts.

b) i could weld (hence Hardrace option) tabs or sheets to fill the shapes. effectively making all the hollow triangles, squares etc a solid object, and this will also leave the bolt holes clear for easy removal.

c) use the new bracing kits as an exoskeleton. i will need longer fixing bolts, but this will be a very easy cut of various sized sheets which will be held in place by the bracing kits. but, this wont make a true flat underfloor.

Has anyone else had a go with this sort of thing? internet doesnt have too much info, on any car. especially when it comes to a convertible where i want to improve rigidity at the same time.

thoughts, ideas, discussions welcome :))