My 1985 Eunos roadster was fitted with 7!! spoke alu rim, but I love steel rim, so did search and got one 14 inch rim 6J with PCD 100mm on Japanese auction. Brand new 4 set rims for Honda car was available at 8000 JPY.

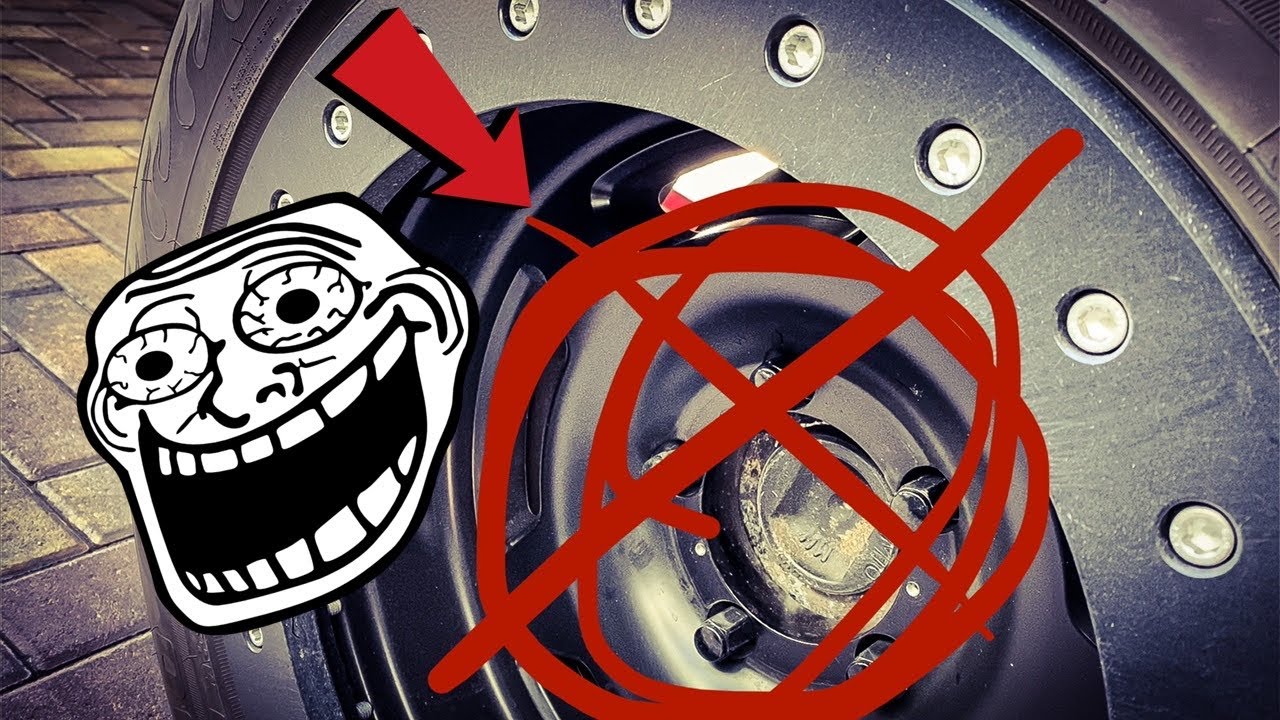

But be careful !! Rim fixing nuts for Mazda have tapered end and only Honda ones have spherical end as seen on the first pic. Only Honda still keep the spherical end but all other Japanese car manufactures are with tapered end.

Why only Honda ?? Because spherical end nuts enable easier wheel centering.

Anyway my 1985 V-Special looks much nicer now. But hub center cap is with Honda logo, as Mazda’s hub centre dia is 54mm but Honda’s one is 56mm-.

The difference in wheel nuts and wheel centre ought to tell you something. Mazda wheels are hub centric, Honda are lug centric…

Thanks for your reminding the technical jargon “hub centric” and “lug centric”.

Another article says that Hub Centric Wheels are centered by the center bore of the wheel and the hub flange. Lug centric wheels are centered by the torque of the lug bolts; rather than the center bore of the wheel and the hub flange.

So, if there is a gap between the center bore of the wheel and the hub flange in case of hub centric, need a spacer to fill the gap. This is theoretically correct but both the center bore of the wheel and the hub flange are normally NOT machined(especially for steel wheel like mine), so not easy to fill the gap in between completely and many people use the hub centric wheel without the spacer.

You can buy spigot rings (hub rings, hub centric rings) to ensure proper fitment.

Usually, aftermarket alloy wheels are supplied with spigot rings to ensure that wheels are safely fitted. Lug centric doesn’t mean that much, except that without proper hubcentric rings, you cannot properly centre your wheels. You might get close, but it will never be perfect.

Extreme outcome of no spigot rings:

http://www.planetsoarer.com/offset/studs.htm

Yes, and lots of people aren’t bothering with them. That’s not a safety endorsement.

Interesting link.

But… wheel nuts/studs and the centre bore do not support the weight of the car.

The CB is to locate the wheel centrally. The studs/nuts then squeeze the wheel onto the hub and it is that interface that carries the weight of the car. Hence why the bolts need strength under tension and not on shear.

If the bolts are not tight enough the friction interface between wheel and hub is compromised which may allow wheel movement result in bolts shearing.

Any grease to prevent the wheel sticking to the hub, or even paint between wheel face and hub face is a no no as that affects the friction interface and therefore the bolt tension/torque requiremnt.

Another no no is putting anti seize lube on the studs. The specified torque settings are for dry fitting. If you lube the threads, the tension created at the same torque level will be much higher and therefore may lead to fatigue fractures in the studs.

If using lug centering because the CB is incorrect with tapered rather than the rounded ones shown above I guess it is relatively easy to not centre the wheel correctly which then results in angular tension on the bolt, which is amplified as the bolt will be over tightened to reach the specified torque as the bite point on the taper will not be uniformly spread thus also imparting a bending force on the bolt. Might get away with it for a long time, but when you don’t. …

So yes, please use spigot rings if using hub centric centering.

Thanks for your kind support ! Well noted.

No worries.

Tightening the lug nuts gradually and doing in a sequence to evenly spread the load, say, numbering the bolts clockwise 1 to 5, do in this order, 1,3,5,2,4 the tapers will pretty much centre the wheel. You will probably only get problems if you tighten one up before the others have been tightened enough to centre on their tapers. This can happen with someone whacking a wheel gun on and doing things quickly.