- My model of MX-5 is: NC 3.5

- I’m based near: Fareham

- I’m looking for technical help or recommendations on: brakes

I got the Frentech kit to refurbish all calipers, and having watched the Flying Miata YouTube on doing the rear calipers, bought some long nosed circlip pliers.

When I stripped the calipers down I was a bit surprised to find mine were different from the Flying Miata ones (no adjustment possible from the outside with Allen key)

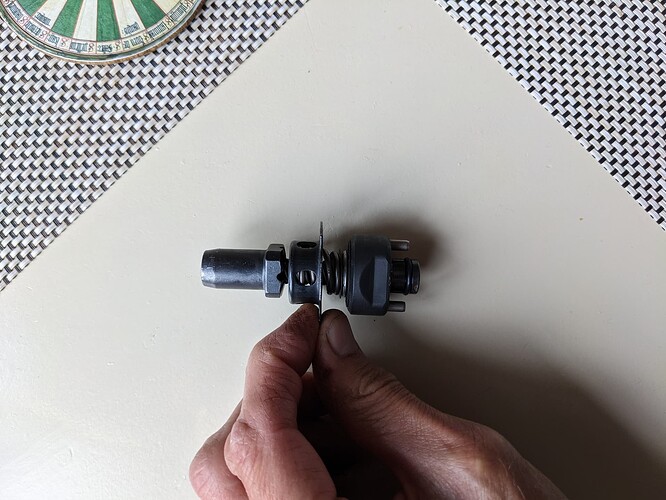

Mine needed a circlip removed from inside the piston which required a spring to be compressed at the same time - which I’ve managed to refit.

However I am unable to replace the circlip in the cylinder bore. This also has a spring that needs to be compressed before the circlip can be locked in place.

I’ve compressed the spring using sockets and a brake piston compressor tool, but it’s almost impossible to get the circlip pliers into the remaining space.

Also I have managed to put a scratch on the cylinder bore - can I try an get that out with 1000 grade paper?

On that note the pliers aren’t the best - just arrived from China with one pin a mm or so longer than the other and I’m wondering if one of the arms is distorted as the don’t meet fully (I’ve tried bending with no success and don’t really want to trash the too (just yet😉).

Anybody who has managed to do this task could you you explain how please.

1 Like

Find yourself a long socket that just fits in to the bore of the piston.

Place the circlip in the top of the bore - the socket on top of it - and give it a swift thump with a soft mallet.

The circlip should pop in to place.

2 Likes

Also - ref the scratch - the cylinder bore in the caliper does not do the sealing.

The sealing is between the seals and the piston outside diameter

2 Likes

Thanks, but I can do the piston circlip, it’s the one in the cylinder bore I’m trying to do.

I’m try to compress the spring on the adjuster rod out of the bore using the elongated nut (from the piston) which goes on the road. Doing this out of the bore, but because it is a very slack thread (worm drive?), the nut is easily pushed back up the road by the strength of the spring.

Sorry, I noticed the title was asking about the piston. I’ve corrected that to read cylinder bore.

Yes - the answer is still the same - use a long reach socket that just fits in to the caliper bore.

Make sure the handbrake mech has located correctly with the two pins.

Insert the circlip as far as you can in to the caliper bore.

Put the socket on to the circlip - then tap it down until it clicks in to place.

1 Like

Okay, thank you. I’ll probably need a long 26mm socket to fit over the circlip.

I’ve reassembled it with the circlip in an I reckon it needs to go down at least 2mm more, which seems a lot.

However, that is with a thin washer and bearing washer not in. I’m 99.9% certain they go at the bottom of the spring. I can’t find an exploded diagram, but did see an RX7 one (and a Toyota) with a similar order of assembly. Do you know if they go there?

It’s difficult to understand how the bearings could have a purpose with the spring so compressed on them. If they are there it will increase the distance the circlip has to go down.

The reason for the thrust bearing is to allow the shaft to rotate so the handbrake can adjust each time you use it ( due to brake pad wear )

The collar and the circlip are fixed when assembled

The shaft is allowed to rotate. - the thrust bearing makes the rotation against spring pressure easy.

1 Like

So just to be sure, the order is;

thrust bearing (closed side downward),

thin washer

spring

collar

circlip?

I’ve got a 27mm socket now, so I hope using a piston wind back tool I can compress everything enough to get the circlip in place.

Your picture shows the correct orientation of the thrust washer & spring.

I don’t remember that spring being so difficult to compress.

I would re-check that the part with the pins has fully located in to the bottom of the caliper ( along with the short handbrake push rod )

Then insert the threaded rod ( red rubber grease on the seal ) - make sure it seats fully.

Place the thrust bearing/washer/spring on the shaft.

Lower the flanged collar over the assembly

Place the circlip as far down the bore as your pliers allow

Use the socket to tap the circlip home

1 Like

Could you clarify the thrust washer goes good side down?

Will be putting the rears together tomorrow. Hopefully

I concentrated on the fronts today.

Can you help me with the new pads also please.

Rears - 1 pad has a clip on an ear - does that go to passenger side and inner or outer?

Fronts - kit has 2 ear clips - which pads do they go on? (Passenger side had one on each pad, driver’s none!).

Thanks again for your advice.

Thrust washer - doesn’t matter which way it goes normally.

The top and bottom washers/bearing surfaces are the working parts.

The clip on the pads should be installed so the disc pulls it down in normal rotation.

The clip is designed to squeel when it touches the disc to let you know the pads are low and require changing.

1 Like

Got the circlip in at last. Had a 27mm socket in the bore and used a piston wind back tool (in reverse) with a smaller socket on the end of it. Very hard to push it down, but at the second attempt I heard a little “snap” as the circlip located. I had to use a socket wrench on the piston tool to get enough torque.

The other caliper went in straight away…