The premise of the 2.3 DISI swap.

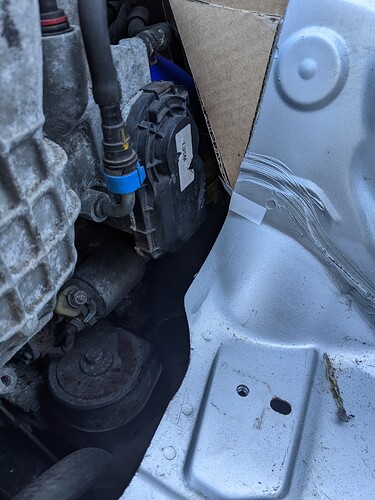

Everywhere I read, all that was mentioned was that the engine would fit but there would need to be some heavy massage of the direwall for the high pressure fuel pump - this is a maybe… for LHD, for RHD seems to be much, much more than this.

So back at the end of 2020 I started working out what I would need, I would point out I have ‘zero’ mechanic knowledge at the time, and had bever even done anything like an oil filter change myself.

most I had done was get my brother to change my disk pads while I got him cups of tea

So planning on having this done in a couple of weeks I started to get some tools

some to note for being excellent (not sponsored by any of these and only posting from experience)

Halford advanced 200 piece tool set - £260, these have been worth the money, some have stopped working but the best feature about this set is their lifetime warranty, I have simply took the bits in that have stopped working (some have snapped, some have had their ratchet stop working) and halfords have exchange all of them free of additional charge and there are enough in this set that I could switch out to another socket size and not stop progress for the most part - downside is if halfords didn’t have that bit in stock you could be waiting a week for a replacement.

Ryobi power tools - I got myself their drill, impact gun, grinder & light, probably about £200 worth. these have been flawless throughout the project, I needed a cordless set as I was originally planning to do it away from my home and wouldn’t have a power point (live in a flat)

Note* I got third party batteries for these, it’s a bit hit and miss but at half the price of the official ones I ran on 2 x 5Ah batteries - I then got 2 more of these, they lasted in use time but their overall lifespan wasn’t great.

Some things to stay away from

Dewalt goggles - I got these half way through the build as my originals where old and scratched to the point it was foggy and couldn’t see out of them, the dewalt ones though had some breathing hole at the bottom and didn’t fit around the nose great - often getting bits flicking up in that small gap!

Another great place I used was autosiliconehoses.com - had 95% of all hoses I needed (I have ordered too much from these at times and due to the slowness of the project couldnt return these, will probably put all these parts up for resale once I have completed the project.) They look to be great quality, few issues with orders and they were always easy to work with and were very helpful.

My thought with most of these tools is if I decide to, I could sell them on later - keep in mind I was quoted approx £6000 for the 2.5 crate swap in a drive in and drive out solution.

Thus far on tools I probably have spent about £700 - 800

Once I started rolling the ball with the tools my next job was to find a DISI engine to put into this thing.

There was multiple options, getting an engine on its own seemed to be approx £1500 and that had the added disadvantage of having to get an ECU to run this setup and rewiring everything to piggy back from the mazda ECU or to completely replace the ECU - instead I found a donor car with the engine in, 90k on the clock and because it was a CX7 rather than the mazdaspeed range only cost me £1500! The clutch had gone because the guy had been towing a trailer but apart from that everything else checked out.

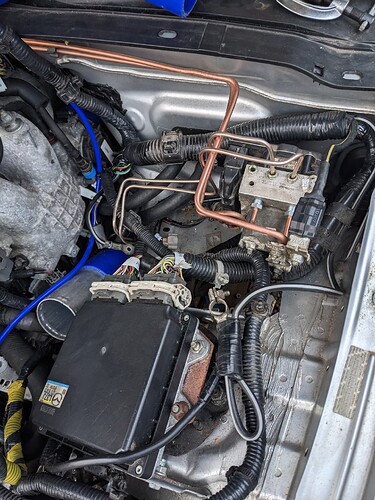

The benefit of this, it has the wiring harness, has the ECU its all mazda and while I saw some work ahead as the cars where made 1 year apart I was of the opinion that anything that had to be kept on the mx5 would be swappable or not much rewiring would be needed.

The first job - get the engine out and strip the CX7 down for parts - selling bits here and there I have made approx £700 back with lots of stuff available to sell, I have them in storage and haven’t really pushed selling some parts - I am estimating I will probably break even on the car once the rest are sold - so a free engine! (excluding mine and my brothers labour)