At long last I got around to changing the weedy headlight bulbs for some a little bit brighter. Compared with the Niseko’s NC1 lights or my Mazda3’s these 25AE NC3.75 headlights are almost useless especially on the dip beam.

Main beam on both sides is a five minute job for each bulb, access is tight for big hands but perfectly manageable from inside the engine bay.

The owner’s manual shows where to squeeze the Dip beam plug to release the connection.

I studied the problem of the dip beams for a couple of days and did some research.

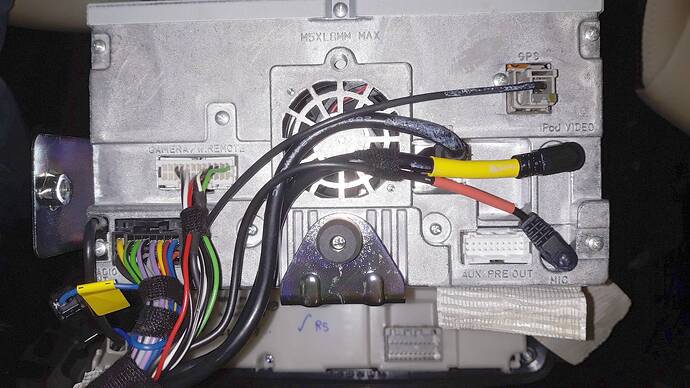

Initially I thought access on the driver’s side can be helped by bending back the wheel arch liner until I realised dropping the fat loom under the slam panel above the light cluster made it quite easy, well, almost easy, and I did not need to move the washer bottle.

But on the passenger side, branches of the loom are well in the way from the wheel arch and the only solution is to move the fuse box back an inch, again helped by releasing the fat loom running from across under the slam panel.

Then left hand only access through here.

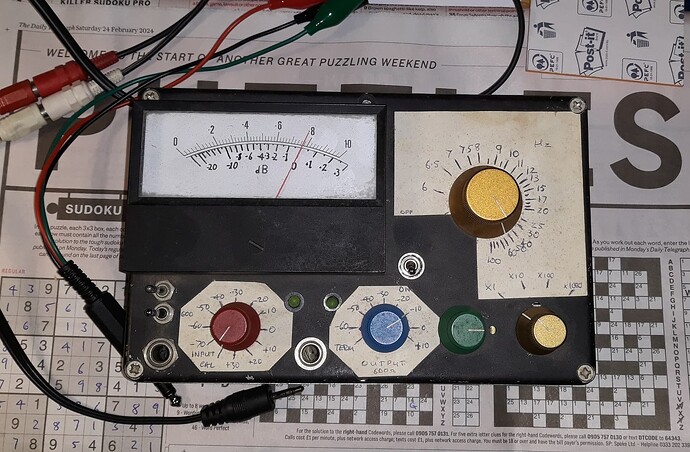

I needed to assemble a fork-tool to push the spring clip because my fingertips were not strong enough at the awkward angle.

Now all they needed to do was hold it in place while the right hand pushed from beside the fat loom going back from the fuse box, suddenly it’s easy, almost no effort .