N.A. EUNOS 1.6 Idle woes CURED!

After owning my eunos MK1 1.6 for a few years and recently been unable to get a tickover under 1000RPM (cold or warm) the engine would idle steady without fluctuating at 1200

the other annoying thing was turning the air con on would lower the idle speed almost close to stalling speed ,could the 2 issues be related??

I got the idea that the iscv would most likely be the problem from a write up in Miatra garage so decided to have a go at solving the problem, my fix is thanks to the Miatra write up,I don’t take credit for the idea,

The ISCV is a sealed unit apart from the inlet/ outlet ports they can to be cleaned when the unit is removed from the TB. The sealed motor coil (that operates the rotating rotor vane of the iscv) alters the amount of inlet pilot air flow, the motor coil receives various ,and varying voltage signals from the ECU to increase or decrease engine idle speed by turning the cutaway rotor thus regulating pilot air to the TB /inlet manifold so if the coil goes open circuit the rotor stays in a fixed position (part open) thus giving you a idle speed about 1200 rpm,moving the throttle body air screw in had no effect in reducing the RPM as per Madza Manual instructions…

I removed the plug and just about managed to get multi meter probes on the 2 pins of the unit without removing it from the throttle body and as expected it was open circuit. The reading you should get at the 2 pins should be 12 Ohms or within 1 Ohm of this allowing for meter error or connecting leads you may need to remove the iscv from car to be certain as its hard to see probes on pins with iscv in place under bonnet

I could not find for sale a decent used one and a new one seems very expensive if you can find one so nothing really to loose by trying to fix the coil as per Maitra Garage write up.Well you have nothing to loose proving you do not attempt to dismantle.

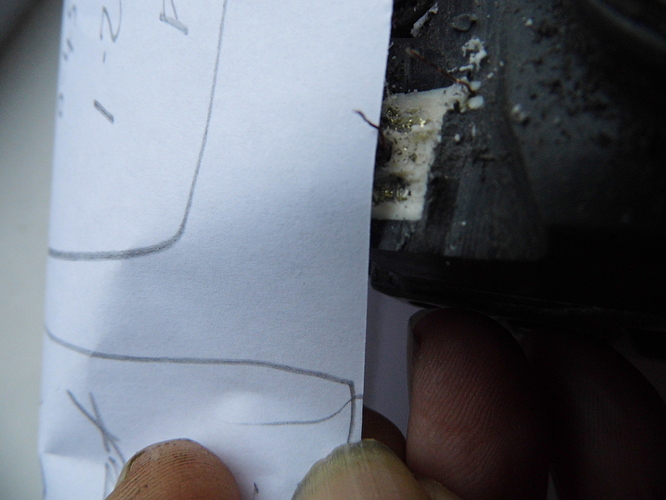

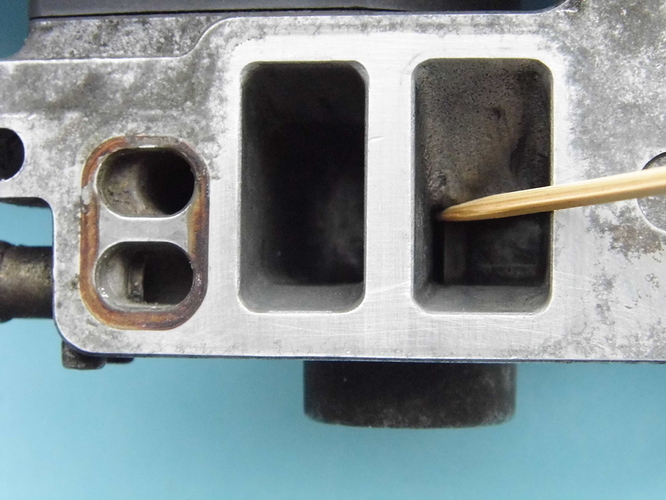

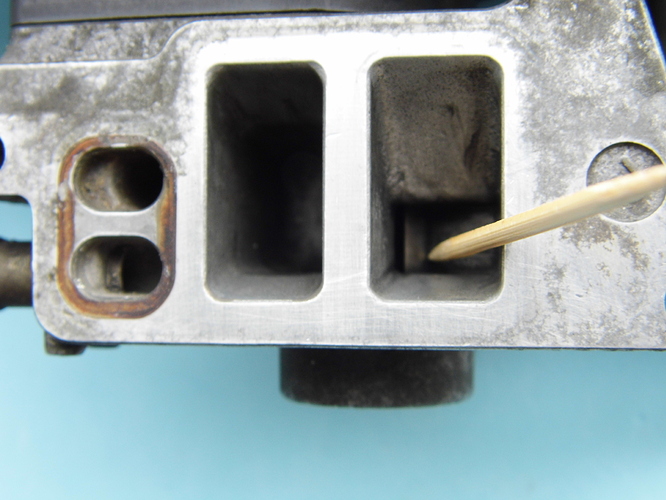

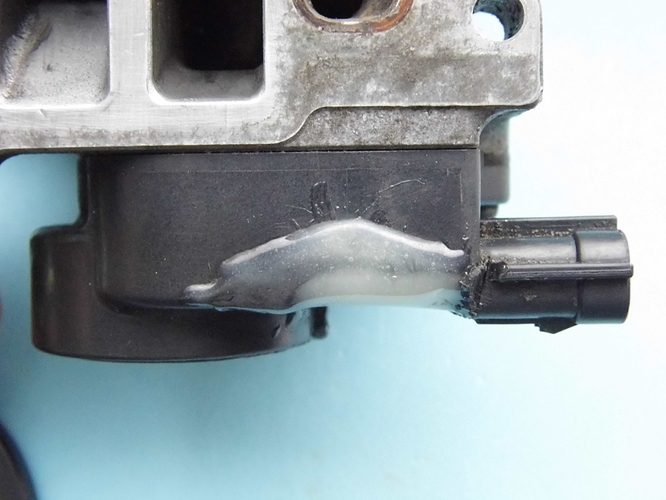

I removed the unit from under throttle body by removing the throttle body from car then I very slowly used the edge of a second cut file with extreme care to slowly file away black plastic type moulding around the area above and at the rear of the plug pins ( see pictures)its important to remove material slowly and with care when the black compound changes to a white plastic compound proceed with even more care and scrape away with a Stanley blade until you find the 2 brass flat pins and the 2 ends of the coil its quite possible the open circuit is at 1 of the 2 pins were the coil end leads have been connected to the rear of the connecting pins as was suggested in the Maitra Garage write up, this proved to be so with my iscv. the wire is very small diam and will easy brake so take great care in cleaning by scraping the wire clean from enamel and re soldering to the rear of the pins, look at my pictures to give you a good idea of were you can expect to find the 2 coil ends ,the coil ends were never soldered at manufacture I think they were only crimped to the pins, and this is most likely why it fails at this point after soldering the 2 coil ends with a small soldering iron the reading at the front of the pins was 11.8 ohms , so I then carefully mixed quick set Araldite and slowly resealed the wires and built up with new material as required when the Araldite set I did readings at the outer connecting pins and still had 11.8 ohms so before replacing the gasket and screwing the iscv back on throttle body I carefully cleaned away carbon deposit with cotton buds dipped in brake cleaning fluid around the rotor vane and air ports. Picture of port with cocktail stick points to the cutaway of rotor in ignition off (no signal or fail position) you may be able to see the small gap for air flow in this position

Also before replacing to the throttle body I reconnected the plug to the iscv got someone to turn on ignition on and by looking inside the port of the iscv I could see the rotor move when the ignition is turned on/off.

It does move if all is ok but you have to be quick to see it move it only turns a small amount.

After refitting all the components and reconnecting the 2 pin plug the idle speed was high on a cold engine 1300RPM then the idle speed came down after warm up to 900RPM, switch on air con ,speed increased for a moment then back to 900rpm , move power steering wheel again slight increase in rpm,on a warm engine at idle I now have a steady 9oo RPM. also small correction to idle speed could now be obtained by the idle screw, follow the Mazda manual instructions to do this. Note: 1 repair done 6 months ago still ok 2: 1.6 engine only 1.8 different unit