Hello everyone!

Some of you may have seen my thread around a month ago regarding my poor car’s engine going the way of the dodo due to leaky oil control rings. Sad, sad times for my little Eunos, however with a lot of hard work, money and swearing she lives once again!

I’d normally try and keep a post short, however this is quite an epic one, so apologies in advance!

Essentially my issues began around 2 months ago when my car began farting lots of blue oil smoke out the rear on startup and when pulling away after descending down a hill; I live in Yorkshire so there’s plenty of them about! I’d recently done a long motorway journey and had run low on oil which was peculiar seeing as the car had been serviced no more than around 1100 miles previously.

I tried to solve the issue with simple things first, PCV valve, refurbed the throttle body and ISC valve, changed the cam cover and CAS O ring, oil changes followed to no avail until I noticed one of the plugs was fouled and cylinder no3 was, scientifically speaking, buggered.

I found myself in a predicament at that point; Did I refurb the old engine by sending it off to be rebuilt? Did I just drop another old mk1 engine in and hope it didn’t go bang? Or did I source something newer, with less miles but a host of problems to overcome?

Me being me I ended up choosing door number three and doing the hard option, which, on balance has been a pretty good decision!

To begin with I had to do some research to find out the extent of the undertaking, and find out what parts I’d need to source. A few chaps have done NA to NB VVT swaps, but as with a lot of things there are multiple ways to skin the proverbial cat when doing this swap. Some folks tore the entire loom out of the car and swapped it for a VVT one, complete with ECU, which I didn’t fancy, whereas others have used the NB engine harness only with a standalone ECU, and others have used the NA harness and spliced in the correct connectors to control VVT and suchlike. Guess which option I picked? Door number three again!

Finding the engine was the next bit, and I managed to source myself a mk 2.5 engine and gearbox with only 46k miles for £325 delivered from a helpful chap at a breakers, complete with VIN, mileage and purchase receipts which is about the best you can hope for ordering an engine over t’internet! Luckily for me I managed to find a fantastic garage to give me a hand with the swap; MX5 specialists are a little thin on the ground here in Leeds unless you fancy going to Sheffield to Roddisons, but it was a bit far for me really. I ended up getting in touch with Rotary Revs in Batley and spoke to their 5’ specialist, Gene. Gene used to race spec Miata in the states and autocross in Japan so it seemed he knew his stuff which was reassuring. I picked Rotary Revs because they rebuild Rx7 and Rx8 engines as their main business so it seemed a logical choice to use a Mazda specialist, and I’m glad I made the decision in the end to use them. They allowed me to come and work with them for 4 days in all doing the swap, helping out, learning and basically being part of the team, so kudos to them for that. It’s not often tuners/garages will allow customers to work with them on the car while they do the job!

Pic of where all the magic happened:

I arranged for the engine to be dropped off with them, and on the Tuesday we had at it, getting the old engine out tout-suite by the end of the first day!

Easy does it!

I spent the day prepping the new engine to go in, I changed the timing belt, aux belt and alternator, replaced the waterpump and cam cover gasket before finding an almighty mess under the cam cover!

Either the engine had not been serviced in a loong time, or the car had been sat for breaking for ages, but the oil was a thick, black goopy mess, and the plugs were filthy black with crud as well. Not a good sign…

Gene and I decided the best thing to do was to get the engine in, run it up to temperature with the crappiest oil known to man in it, and then drain it all out for some fresh stuff to hopefully clear it out a bit. In the meantime I put the cam cover through their nice cleaning machines they use for restoring rotors and paint it gold to match my rims!

Eventually we got the old engine out to find that the crank oil seal had also gone, which explained why the car kept doing a wee on my drive all the time; I think we caught it in the nick of time!

Sooo, this is where everything began to get hard! There’s a lack of photo’s for this bit, and there’s a reason for that, which is us basically getting our heads around all manner of gremlins that we encountered!

To begin with we found that the fuel rail for the NA wouldn’t fit the NB which runs a returnless system, so I had to go shopping for a nice new Sytec fuel pressure regulator… £115, ouch!

After sourcing an FPR we were able to run the NB rail and use my nice “Flat top” intake that folks rave about after all, as it was looking like the other option was to use the NA intake and fuel system, however neither of us were sure it would work due to the different fuel rates, so luckily all worked out ok in the end!

All assembled!

Once the rail and intake were sorted we could nearly get the engine back in, but while it was out I changed the clutch for a nice new Exedy setup and did all the bearings while I was at it. I also changed the gear shift boots, filled the turret and box with redline MT90 , and changed my tachometer because my old one was starting to graunch in it’s advancing years!

So, box and engine were reassembled on the pallet and dropped back into the engine, at which point we were on day three and I had to go back to work! it was nice to leave her looking like this however!

As you can see the coil pack had to be re-used because the COP system used by the NB wouldn’t work with my NA harness, and we also added an IAT sensor as well with the intention of removing the MAF later on. Trouble is there’s no room to mount the coil pack at the rear so Gene fabbed me a bracket for it to sit on in the meantime. We also found out after turning it over for the first time that the alternator was overcharging the system, and then the starter motor failed, so off it all came to be swapped over for NA equipment!

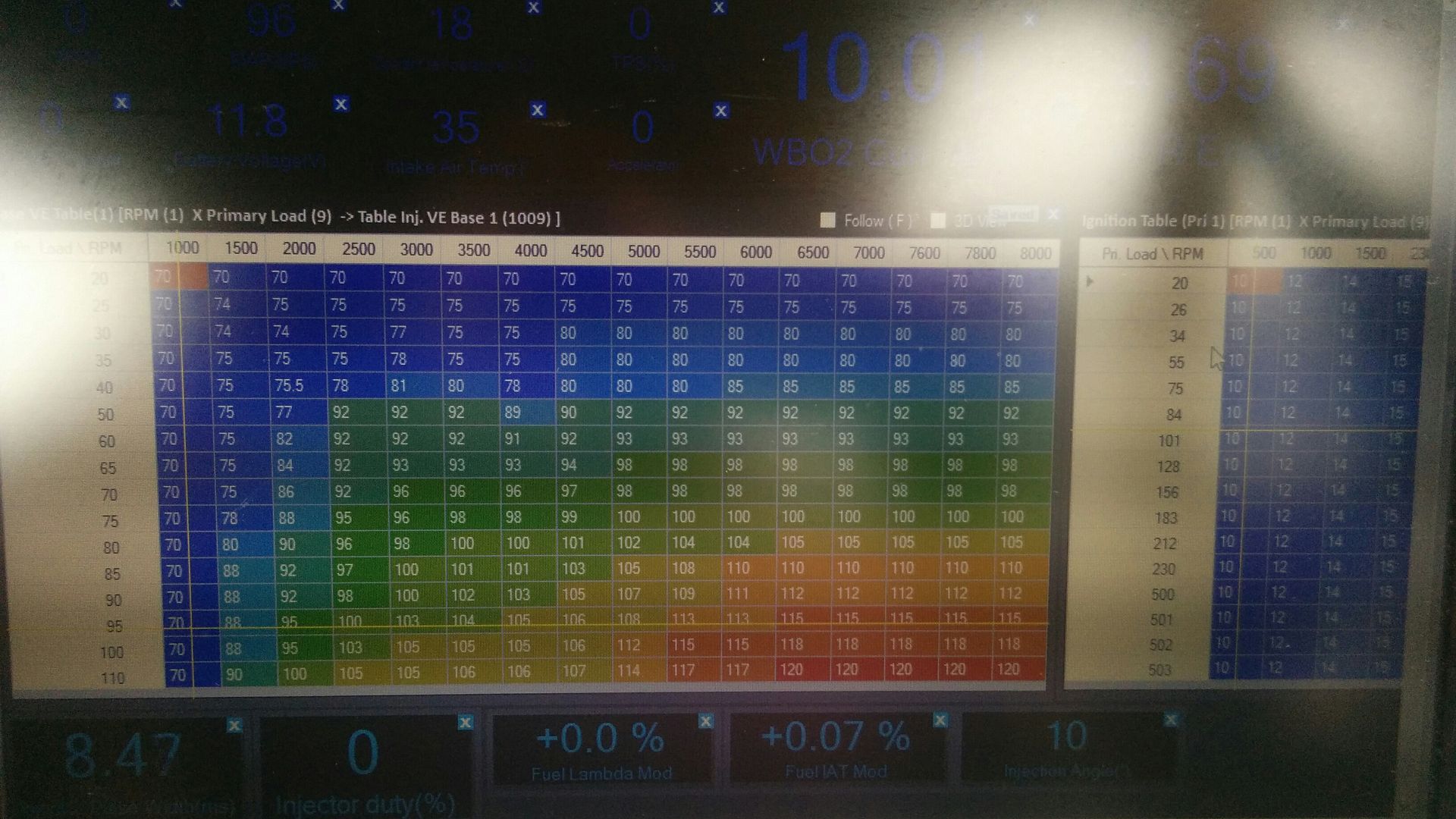

Eventually we got it started up and running, but barely. I went for an ME221 ecu over a megasquirt as I’d have needed at least an MS2 and VVTuner or ideally an MS3 to run the VVT, but read good things about the ME221’s and found out that even the ECU’s for the 89-94 cars could run VVT so bought one. Initially I bought an ECU for a 99-05 car for £100 more, but realised my error and asked for my order to be amended, which they duly did, however it’s now 3 weeks on and I’m yet to receive all my refund for the error. Gene is more used to Megasquirt, Haltech and Motec so this one was a new experience for us both! I found the interface in MEITE very easy to use, however the basemaps on the supplied USB were way out for some reason so we had to essentially start from scratch on the VE table, tuning every parameter as we went.

It was very slow progress!

Upon first startup several issues presented themselves; Firstly initial catch took about 4-5 cranks to start the engine, which would then settle into a very loping idle of around 1600-2200 rpm. While this was going on there was a really loud, honking resonance coming out of the intake, it was really loud and drony and very annoying! You could also hear the idle shutter valve opening and closing repeatedly until the car warmed up. On the dyno when under more than around 3/4 acceleration you would get hesitation due to the acceleration enrichment settings being incorrect which would cause the engine to almost cut out. Either way the biggest issue was that the fans weren’t running and the car had no functional temperature gauge because the NA temp sensor went into a blanked off area on the NB block, more incompatibility issues!

Eventually we fixed the fan issue by changing the jumper settings on the ECU, but by this point we were out of time and I had to drive it home honking and stuttering like an angry goose with a speech impediment. Not cool…

We did manage to get one dyno run done before I left which recorded 148bhp, two more than stock so looking promising considering I have a very rich VE table for safety, no VVT and we’ve performed no timing adjustments at all!

Thankfully this weekend I managed to get the laptop out and have a crack at it, solving many of the issues. A member of Mx5 Nutz sent me a link to other basemaps to try designed for the 2.5 ECU which helped to solve a lot of my issues. Turns out the idle frequency of the NB is different to the NA so changing the settings to NB stopped the horrible loping and honking noises, and the acceleration enrichment map fixed all the stuttering too! Winner!

Initial catch is still an issue, but for the most part the car drives like stock now. I changed a lot of the PWM settings for the high idle and now have a steady idle around 960-980rpm, the acceleration enrichment at base was way off, up at 12 when it needed to be down at 3 so that explained why the stuttering was so pronounced.

After all this, I am pretty pleased with how it turned out in the end. Like I said I still have no VVT and a rich basemap, so it’ll be back to the dyno next month for some extra tuning and VVT hookup, so I’ll update to let you know how it goes. Without VVT the engine feels a bit anaemic at low revs, but it certainly pulls hard after around 5000 rpm which I’m very happy with. The engine is also much smoother than before, and the new clutch, oil and gear boots have made a massive difference to the box compared to my last one; real rifle-bolt action now on it which is awesome!

Had I known the VVT swap would be so expensive I’d probably have rebuilt my engine. It’s probably cost £1000 more than a rebuild all told, however discounting the clutch and other ancilliaries I replaced at the same time, I’d say more like £750 is a more realistic discrepancy. If I get the same mileage out of a 46k factory unit as I would have got out of a rebuilt NA engine with 10 years and an extra 65k miles on it then I’ll be very happy, and by the look of it I should be able to make some useful gains in bhp while I’m at it. The ME221 has been a bit of a mixed bag which is a shame. ME still owe me £13 because they deducted shipping and handling off my refund even though it was neither shipped nor handled, because I notfied them of my incorrect order the next day, butthey’re in the process of reimbursing me for that. Tuning wise, some of the tunes they have available are spot on, some are not, however a lot of that may be down to having such a frankenstein setup so I’m willing to overlook that. The only gripe would be that it seems no matter what I apply in terms of map to startup I can’t get the engine to catch cleanly within a few cranks, but I’ll keep working on it and hopefully find a solution.

Overall though I’d say the extra money was cash well spent because the amount I learned by working with a proper mechanic and getting stuck in was 100% worth it. I’ve had the chance to build a relationship with a tuner I trust and feel I can rely on them to help me out in the future so yeah, it was a success in my book!

Now only if I’d swapped it for one of these…

Cheers!

Alex