- My model of MX-5 is: 2.0 ND2

- I’m based near: South Lakes, Cumbria

- I’m looking for technical help or recommendations on: Power Control Module Connectors Access.

Hi,

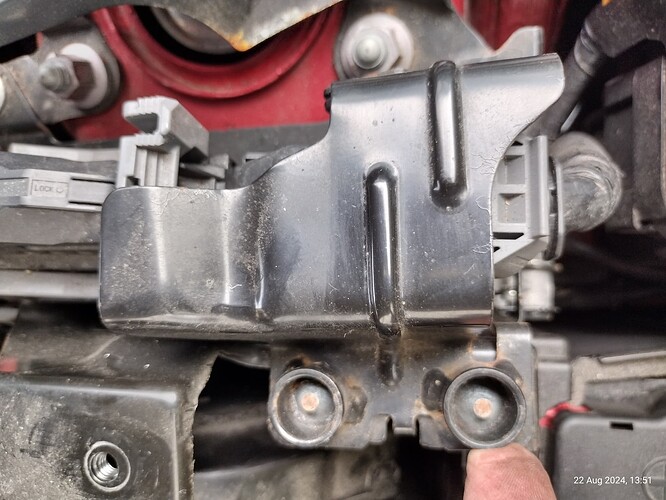

I need to gain access to the Power Control Module connectors to check good connection and possibly clean the pins/sockets with electrical cleaning spray. The ND shop manual PCM REMOVAL/INSTALLATION [SKYACTIV-G 2.0] | 2016 ND Shop Manual instruction (hexorcism.com) suggest that the connectors are easy to access for checking. However the connectors on my car have a metal guard over them with two fasteners for removal (see photo below where the tip of my finger is just visible at the bottom right pointing to one of the fasteners). There seems to be a nut tightened onto each of what look to be welded in studs underneath where I am pointing but non of my sockets will fit them. Is this deliberate to make them tamper proof and has anybody else had cause to gain access to the PCM connectors? Any guidance would be gratefully received. Thanks.

They are a security feature that is required on UK spec Mazdas. They are sheer bolts (same as that found on steering locks) and require drilling or chiseling out. If you have a rounded nut removal set, you may get lucky with one of those.

1 Like

Hi Robbie,

Thanks for your input. Are you saying that what can be seen down the short tubes welded to the bracket are what is left of the heads of the “shear bolts”? I couldn’t imagine trying to chisel them out or trying to drill them out as the bracket is not that strong. The shape that is formed around the studs is conical making it very difficult to grip in anyway and the tubular sections surrounding them severely restrict access . Also what feels like nuts on the underside of the fasteners are very difficult to access without removing the whole assembly and to remove the assembly you have to first remove the connectors (Catch 22!). I wouldn’t like to grind anything as I would be worried as to where all the metal fragments may end up. It begs the question how does a Mazda Dealer deal with this (excuse the pun)? Do they have some sort of special tool? My car is showing a recorded P2502 DTC which is intermittent and the first point of inspection suggested in the online ND shop manual is to inspect/check and clean if required the PCM, battery and alternator connections.

I shall look into getting a rounded nut removal set but I think the problem may be getting one down the bore of the welded on tubular sections.

The nuts underneath are welded to the bracket so can’t be undone. The whole point of them is they are difficult to remove. A dealer would probably drill them out (use a vacuum cleaner to suck away the swarf) or use a rounded nut extractor. From my experience, the PCM connectors will be good so would only disturb them as a last resort.

1 Like

Hi Robbie,

Yes agreed. I have purchased a rounded nut removal set but I will drive the car a bit to see if the fault re-occurs. As said in the manual the first thing to check with this fault code are the Battery, PCM and Alternator connectors. I have checked the battery so far but to check the Alternator connector you have to move the PCM anyway. If I get the fault again I will try to check the alternator connector before moving on to the PCM connectors.

Thanks for your advice, much appreciated.

Yes, the diagnostic procedures in the workshop manual always tend to put the PCM connector inspection early on, the rest of the world don’t have the shear bolts so not a problem for them. The shear bolts can be quite expensive too so checking the connectors here turns out to be a labour intensive and expensive exercise!

If I do it I will just replace them with normal bolts!