- My model of MX-5 is: mk1

- I’m based near: Central Scotland

- I’m looking for technical help or recommendations on: tools, for panel making.

Just after some recomendations for tools for making some replacement panels for my mk1. Ive gotten what i can online but with a two week break from the workshop i wanted to ask if anyone has some must have, should have, could have tools that they would recomend?

So far im working with:

Vice

4" grinder for grinding and cutting

Metal snips

Nibbler

Various pliers etc

Ive been looking at a metal shrinker, stretcher. Looks ideal for some shapes but expensive. Air cutter looks like it would come in handy but unsure if totally necessary…roller as well im not exactly sure if this would be needed. The metal table ive got has a fairly large radius for hammering over the end of.

Any advice is welcome!

Hi. Can’t really help with tools but I’m very interested to follow your progress.

Are you planning to recreate the original panels or create something custom?

Please share what you do.

Cheers,

Guy

An English Wheel allows simple fabrication of compound-curved panels, almost no hammering involved.

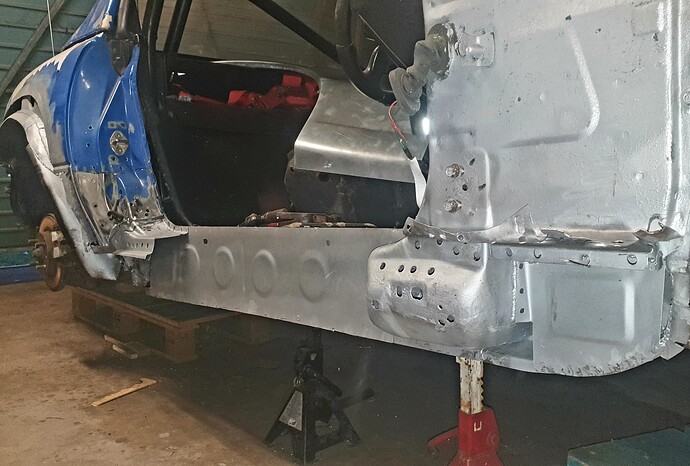

So ive managed to get most of the panels required but for some internal stiffening structure, inside the sills and at the front wheelwell/floor area i need to make some new panels. I really want to get something as close as the original though.

For the sills im planning to take some dimensions to order a laser cut a panel, and in the absence of any real metalworking tool i can possibly 3D print a die to get some of the stiffeneing structure formed, thats the plan at the moment!

Saw a great video from yorkshire car restoration showing this very thing. Looked ideal.

Dominic Chinea from the repair shop (bbc) has a YouTube channel and has been re-manufacturing Ranalah English wheeling machines. It’s an interesting subject to learn about. https://www.youtube.com/playlist?list=PLPmNdN-4RSYJuLVqX7pmRIuaNRtxG0HbC

Awesome, i’ll take a look!

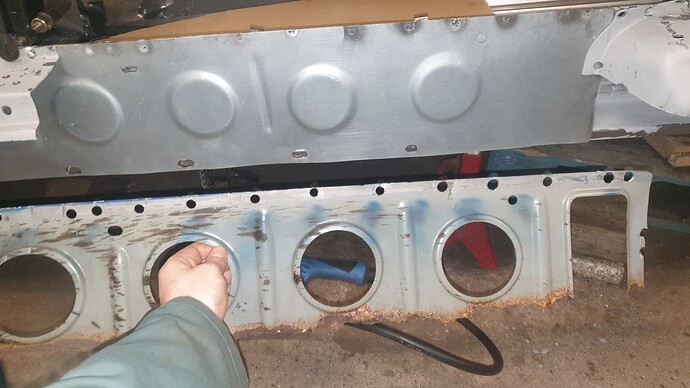

Hi Togs - wee update for you. Measured up the inner stiffener i had to remove and laser cut a test panel in wood. Im going to get these laser cut in steel in the next few weeks. Its not going to be exactly the same but should look similar after pressing the ribs and dimples.

That looks great

From what you said am I right in thinking you’re going to create a lip around each hole to give it strength?

Similar to what a dimple die gives?

Yeah thats the plan. Ive not got a bead roller so I’ll need to just press with a dimple die. The ribs ill need to 3D print something to do the press so i’ll be interested to see how that goes!

Update: ended up not getting a panel lasercut. Too expensive. I made a template in wood i could check then cut in galvanised sheet. The 3D printed pressed worked ok! Not perfect but im happy with the result.

1 Like

Also, heres the centre stiffener removed for reference. There was really not a lot left at the bottom.

1 Like