While the cooler weather is here I have decided to refurbish my wheels ready for the spring.

I wanted to change the colour from a Steel colour to a Silver colour that was a bit brighter, since last summer.

I had left it until wintertime because I also wanted some new tyres fitting in January 2008.

I once saw a 10th anniversay edition with polished alloy or chrome wheels, many moons ago, that rather took my fancy and have since then always wanted something similar.

The following is how, with pictures, I set about refurbishing them.

First task was to find a litre, of the silver colour cellulose that I liked, as I intended to respray the wheels with a small spray gun rather than the tins of spray paint that you can buy.

After removing the wheels I took them to the tyre place that I would be buying my new Toyo tyres from, to get the old tyres taken off the rims.

This is a picture of the wheels before I started to refurbish them.

Back home I started to clean them up on the inside with a wire brush to remove the build up of corrosion on and near to the tyre bead area.

All balancing weights were removed and the rest of the wheel was scrubbed and then power washed to get them clean ready to start removing the paint off, of the outer rim area.

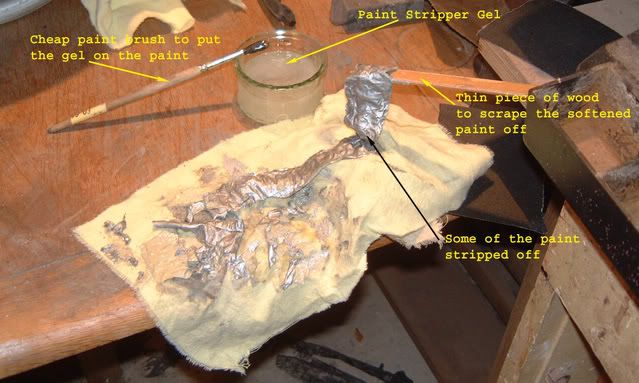

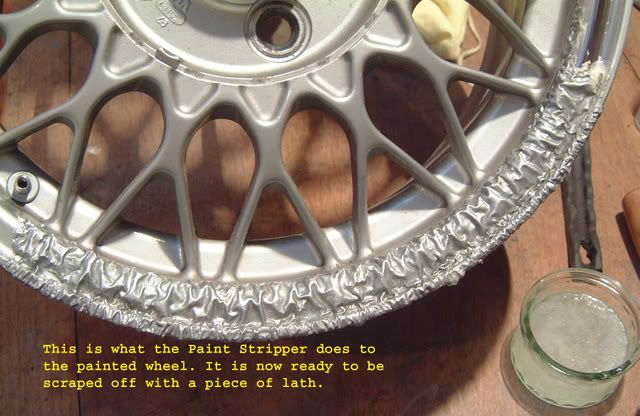

Removal of the paint was quite easy, using paint stripper as shown in the photo.

When I had removed the paint I realised the reason that the whole wheel had bean painted. Something had corroded a small area on the rim that was originally unpainted.

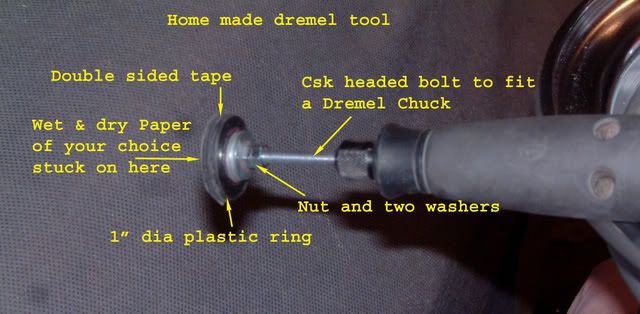

This small area was ground back to remove the corrosion and polished using a small home made tool for a Dremel.

I then set about removing some other small imperfections with P320 W & D paper.

As I only have a wood turning lathe I didn’t think I could use this to help to smooth the alloy with wet & dry paper.

I could have done it by hand but it would probably take me a lot longer.

At this point I packed up for the day to sleep, on the problem.

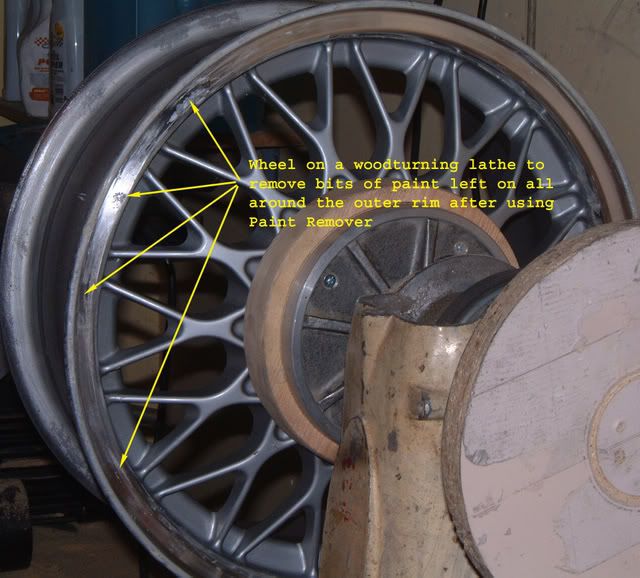

After thinking about it on and off overnight I had an idea of making a false faceplate that would fit in the centremost boss and the outer lip that locates the BBS centre that covers the bolts up. The wheel could then be held in place with 4 large screws and a washer screwed thro the 4 bolt holes.

I checked it was running true, set the motor belt to the slowest speed, and then gingerly pressed the starter button.

Fortunately the wheel was running true, so out came the cork sanding block and P320 grade W & D paper to start removing the bits of paint still left on after using the paint stripper. I continued to use P600 and P1000 grade paper to remove as many of the small scratches as possible.

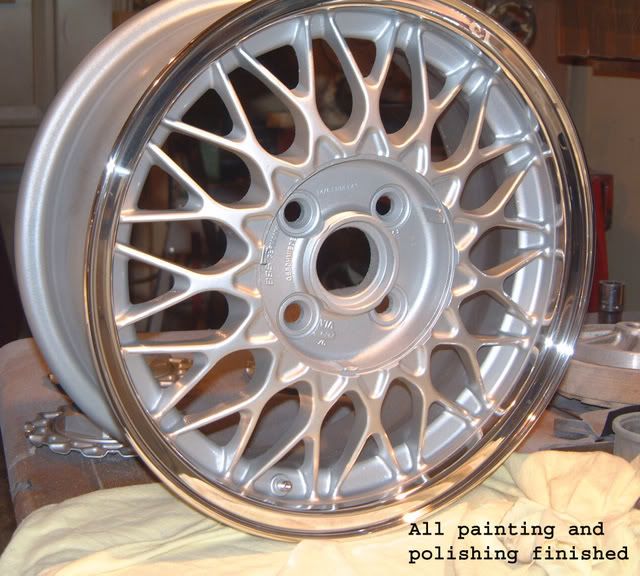

After I had cleaned all four wheels up I removed the false faceplate from the lathe and got out all the buffing wheels I have from 12” dia down to 1.5” dia and three grades of buffing compounds. All wheels were buffed and polished using the wheels and compounds. The wheels were offered up to the buffing wheels and polished with the different grades and sizes of buffing wheels. Parts of the wheels were easier to buff with 12” dia wheels and others with 8” dia wheels. The 8” dia wheels were 0.5”wide and could be distorted to enable them to get into the rim lip, by putting more pressure on the buffing wheel than normal. This is the wheel after finishing the buffing and polishingwas completed.

After I finished polishing the wheel I masked off the polished rim ready to spray them.

Parts of the wheels that were corroded were treated with an etch primer and the rest of the wheels were sprayed with grey primer before spraying with a top coat of silver paint. I then decided only to spray the painted area of the wheels with clear lacquer .The polished part of the wheels were given three coats of wax polish.

After a couple of days the tyres were fitted, but not before the fitter was told how careful he had to be not to damage any of the wheel in the process. The fitter lads were great, the inserted new shields on the clamps that hold the wheel on the tyre fitting machine and a new tool that turns the trye edge onto the rim. They also found some carboard to put the wheels on instead of the concrete floor. They even fitted some nice SS valve caps for free to finish the look off. You can just make them out in the next picture.In the last picture it looks as if one isn’t fitted but it is a trick of the flash.

They look quite striking I think, and was worth spraying and polishing them up.