One of my rear brake calipers was seized,it wouldn’t adjust with the 4mm allen key and it was binding so I ordered a new piston and seal kit and rebuilt it and took some pics along the way.I thought it may help somebody else. My piston was very rusty but the rest of the caliper was ok.

New parts consisting of seal kit/new piston/new copper washers

Removed caliper-note very rusty piston

First stage was to remove the piston-this was seized and took a lot of soaking with gt85 and a twisting motion with grips to get moving

Then I used a footpump to gently pump the piston out WARNING go slowly and use a bit of wood and cover with rags to prevent injury

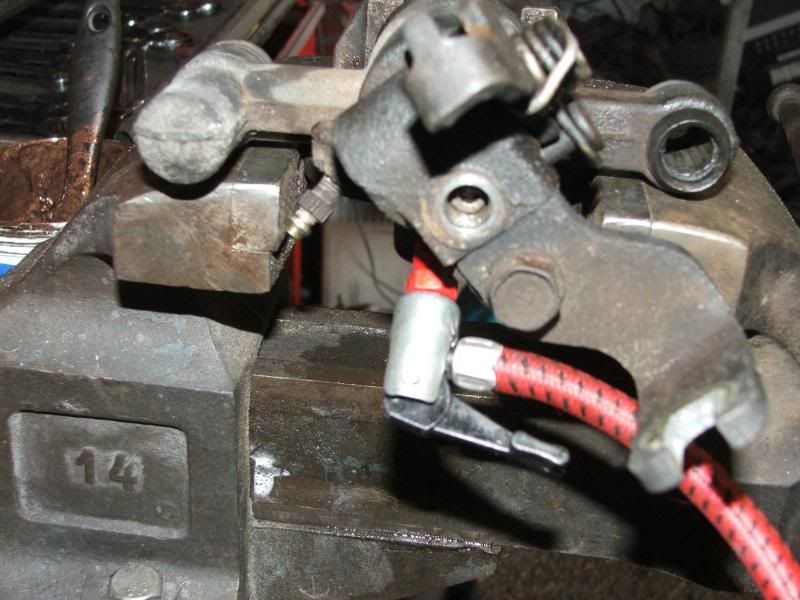

This picture shows using another bleed nipple in but just loose enough to allow air to flow

you can now remove the dust seal , piston seal -missing from picture and auto adjuster for the handbrake (this unscrews)

This is the view inside the caliper,as my handbrake part wasn’t seized and I had no leaks from around the handbrake lever I decided to go no further.

I cleaned out the recess where the caliper seal sits,blew out the inside of the caliper,refitted the adjuster and fitted the new seal and lubricated it with red rubber grease

I obtained the replacement piston from Autolink and there was a difference in the rear of it. The original one had 4 cutouts and the new one did not. Now I initially thought that the auto adjuster sits in those slots, but it has 8 ribs??

a close up pic of the auto adjuster,picture from http://www.miata.net/garage/ebrake/index.html

Next the difficult part you have to fit the dust seal and piston,I tried fitting the dust seal to the caliper first and then trying to push the piston through the seal,but in the end I put the seal on the piston and left the ridge that fits inside the caliper just off the end and getting a another pair of hands to hold the piston while I fed the dust seal into the caliper-you need a lot of patience but it will go in eventually.

seal fitted to piston

Finally in

Refit to the car using the supplied grease to lubricate the guides adjust the piston in using the 4mm allen adjuster just so the pads touch the disc and back off a 1/3rd of a turn

4mm adjuster

and then bleed out the caliper and pump the pedal a few times BEFORE adjusting the handbrake.

Once I had bled it out and adjusted the the handbrake,it was a success no more binding

Just a couple of pictures to finish off with

Old piston showing corrosion

Old parts