Hi everybody,

Can anyone tell me the best place to try for a replacement rear deck panel and approximately the cost. My Mark3.5 sport tech’s panel has at some point been damaged and when resprayed they’ve used silicone in paint which has caused issues with the finish. Having been to professional coachwork body repairer to have this put right because of the silicone contamination they won’t touch it as they can’t guarantee that the paint won’t once again come up with what looks like orange peel effect - so I need to replace it as it’s driving me mad! Will add this was done prior to me purchasing the car and I’ve only had car 5 months. Any help would be much appreciated - Kim

I would check on eBay, they often are advertised. Another idea would be to have the existing one wrapped if you can get a colour match.

‘Another possibility, search for Breaker link on your search engine. On breaker line you put in the details of the part you require and this info is forwarded to car breaker yards. You may even get one to match your existing colour!

Hi

I could be wrong here but when I was looking for a PRHT I found this on quite a few cars.

I don’t think they had all had resprays, I am sure this is a known problem with the composite panels on early models. Strangely the ones I noticed most were on the Galaxy Grey, I know this does not help really but because it is not caused by silicone contamination repair should be easier, I think it is more a water absorption issue.

This is a well known problem with composite panels and some flexible plastics.

They need to be fully dehydrated (baked at about 80C for a few hours) and thoroughly sealed before even thinking about painting with a water-based paint.

They trap moisture, and when It freezes and becomes ice it swells and splits the composite material. It usually shows as pimples or blisters, or if in a big way as a rash! (Badly finished moulded boats can suffer with a winter rash like this).

I first discovered a related problem a couple of decades ago with flexi-rigid printed circuit boards, the flexi layer trapped enough moisture such that if it was soldered the steam split the board and broke the connection through the via! Write-off at £350 for each prototype. Ouch!

The flexi-board for car instrument panels can suffer the same problem if double sided.

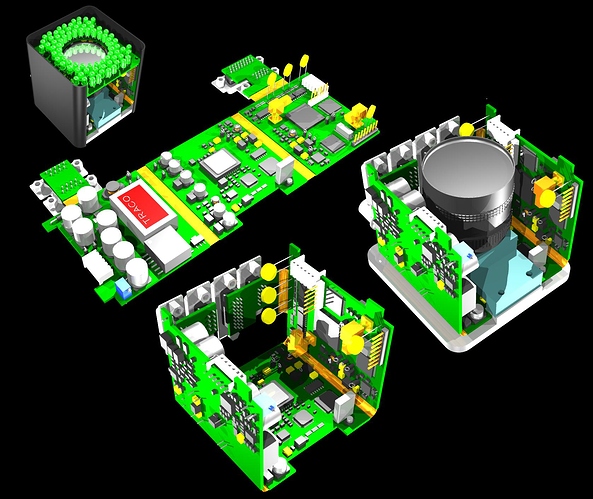

This picture below was a first-try CAD mock-up of the assembly to check on component clearances, and the moisture problem lay in that yellow central flexible mylar(?) layer shared across the whole structure.

Did you manage to repaint this panel? How much does it cost?