a must for owners to check

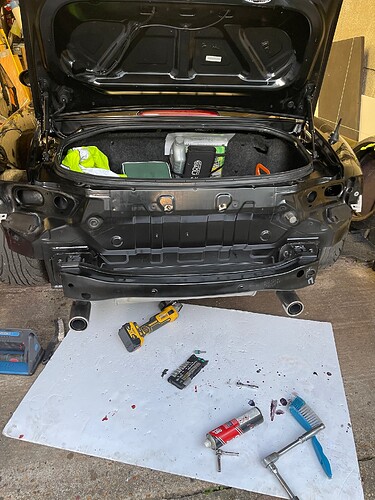

Exposed mine today. Looks pretty typical. The car is ‘06 so I would t go ripping your bumper off in a panic.

Interesting how clean the rest of the body panel is.

Only a quarter was more than surface rust after eighteen years.

A bit of rust treatment…

Then some straight to rust Hammerite.

Whilst buying all the stuff for an invisible repair for the rust around the number plate lights - aerosols for primer/top coat/ lacquer ( just a tenner if you know where to look) I came across an endoscope by Draper for £16. Sucked teeth, but given the problems of the MX this did seem sensible. Draper always look over-priced to me but a reliable mid-range option so it should be a little above eBay hopefully?

Good to get an idea of where to plunge my trombone cleaner too…

Check for bladder/ rectal polyps too? Ok, maybe not….

The patches behind the rear crash structure are, it seems, a rather common issue. My very low mileage “Sunday only in the dry” NC 3.0 got lightly rear ended ina Tesco car park (it was hit and run). The rear clamshell had crazing in the paint so I decided to remove it and make a proper repair. I was horrified to discover the extent of the corrosion under the crash structure. One side required a metal patch repair before the tub areas were epoxy zinc primed and painted. The crash structure was blast prepped, then primed and painted in the same manner. The mating faces were sealed with silicone before fully bolting back together. It seems that Mazda bolt two pieces of bare metal together before painting. How stupid is that?

The crash bar may be HSLA steel which, depending on the exact type, could be very corrosion-resistant as well as being thick. The tub won’t be.

Thats outrageous for such a young car. Been going on for years and hardly a brain-teaser to get it fixed: just a thin gasket perhaps?

From the posts so far, it sounds as if the parts are bolted together before painting, so that’s the issue. Apart from a probable phosphate dip, there is no protection and it traps water too.

I’ve saud it before, but there’s an old adage that most cars are designed to be driven hard for ten years, then scrapped. These days, the design life of some makes is even less. We keep cars on the road way beyond this, so it’s not surprising problems show up.

Yes, truly outrageous. Agreed. Best solution would be for Mazda to bulk paint the crash structures and fit them to already painted tubs. After all, the crash structure is totally hidden from regular view, is a ‘common component’ and could therefore be painted in ANY colour. Production engineering at Mazda simply need to resequence the assembly process. It just means moving a couple of location/action boxes on the flow chart. Given that the mating faces are not, by good automotive engineering standards, a flush fit, the use of a thin gasket would not guarantee success. A non-setting viscous sealant is commonly used in other areas of A.E. and would work well. I used bathroom silicone sealant as it was readily to hand!

Mine has been wire-wheeled / chemically converted /Hammerited./ wax oiled. It probably won’t have a significant effect on the death of this car, but it’s been very satisfying ![]()