Sorry if this has been covered before but upon inspection of my sills it appears they are rusted through.

Does anybody know of anywhere apart from MX5PARTS that sell sill repair panels?

Thanks,

Craig.

Sorry if this has been covered before but upon inspection of my sills it appears they are rusted through.

Does anybody know of anywhere apart from MX5PARTS that sell sill repair panels?

Thanks,

Craig.

How bad are they? Mine have coroded a bit near the rear wheels and I have ground and cut the rusty bits out and made some steel panels to weld in. Hopeing to get that done this week. Fortunately, from the the back end of the sill it is only about 8" long .

hi pollyanna keep use informed with the work you do looks like a good project keep the photos comeing

Moss also sell the repair panels; I think these are the same Chinese-made parts sold by MX5parts. From what I can gather from those in the trade, they’re rubbish (“metal is too thin”). Depending how extensive the rusting is, a proper coachworks should be able to fabricate “sill” bits from scratch; some I think use Ford Escort bits; right curvature, and decent thickness of steel.

I had the passenger sill on my 96 Roadster done last summer as part of a total respray. I think I had caught it in time, when a single 50p sized hole appear. All the metal from the arch to the seam under the door was cut out and replaced with fresh metal.

The driver’s side now shows 3 pinholes; the metal is clean, but leave the car in a garage for a few hours, and little drops of water will appear. The panel is doomed. Coincidently, the car is now back at the same coachworks for crash repairs, and this sill will be attended to FOC.

How long the repairs will last is anyone’s guess. I suspect the only surefire repair is to replace the entire rear wing with a new panel from Mazda. My understanding is that this is actually a very straightforward job.

The rusted area is at least 18 inches long so it looks like a full sill is required.

Does anybody know of someone decent to do this in or around the north east?

When I had cut all the rusted metal off back to good metal I was very surprised how thin the outer curved skin of the sill is, I had intended to measure the thickness out of interest but forgot, blinking old age again. I will try and do it tomorrow if this old brain remembers.

These are the pieces of plate I made to fit the cut-out part on the sills. By thw way I measured the thickness of the metal the sills are made from and it is about 1mm, it looked thinner than this but it may have been the cut edge of the steel being rounded off a bit or something.

I will post another picture after I have had it welded in.

I had the two sills MIG welded up today, with the steel patches I made, by my son who works for a steel fabricator. His boss kindly allowed me to take my car into his workshop and #one son welded it during his lunch hour. It took 55 minutes to weld all three plates in. The MIG welder was a bit too powerful for welding thin car plate but it turned out OK. Below are a few pictures of the welds and grinding the welding back to the level of the car panel’s. This took me about 90 minutes to grind them back. Next job is to use a small amount of body filler to improve the curvature of the repair. That’s tomorrows job.

looks great smooth rub of filler and paint and your done, what paint are you going to spray the sill with, did you also spray all the cavity with the section cut out

Am using Satin black from a spray can. I am going to spray the cavity after I have finished painting etc. I didn’t want to risk any preservative getting onto the outside of the repair. IF I can’t reach the rear end of the sill from under the door sill plate I am going to drill a small hole, large enough for the spray tube, in the underneath side of the repair and spray from there. I will then use a rubber bung to reseal it up again.

Out of interest, the off side sill was far worse than the near side sill. The near side, within the sill, was like it had only been built yesterday

Hi

That’s actually not a good idea, the wax can catch fire, ask me how I know! My sill got awfully hot all along its length before I twigged what was going on. Fortunately I extinguished it before any real damage was done, but any later and it may have been a different story. Much safer to inject the wax when all the welding is finished.

Alan

I thought this too.

I was standing by with a fire extinguisher just in case, and there was a lot of smoke from old preservative.

I have just been in my garage to fill in any undulations between the new patches and the original sills. I am quite pleased that I only needed about 1 teaspoonful of filler for the larger patch and about half a teaspoonful for the small patch. The patches lined up with the sills very well, which just goes to show a good finish is all in the preparation. 15 minutes in the morning to smooth the filler down and then the primer coat can go on.

Just had a quote of £600 labour plus price of sills to repair.

Does this sound ok or dear?

Craig.

How far along from the front/rear of the sills need repairing, is it more than my pictures above which is about 8" long from the rear only?.

Its mainly right in the middle, I am at work now but i could stick some photos on later?

Mine took me 3 hours to grind the rotten rusty metal back to good metal and to make the plates that had to be welded in.

Welding took my son near enough 1 hour to weld them in.

I took 1 hour to grind the welds level etc then 10 minutes to put some body filler in the slight hollows to get the shape back.

The filler took an hour to rub down, get level and re-do where there were a few air bubbles in the filler.

Spraying and rubbing down with high build primer, grey primer and top coat took in all about 1 hour. So to be on the right side of time say eight hours in total for me to do the repairs, not an experience body shop repairer, this may give you some idea of the cost depending on their hourly rate.

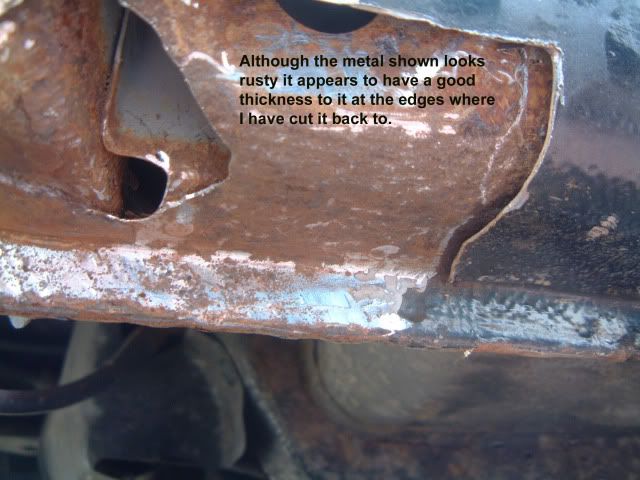

Here are some photos of the sill.

Could these be patched up or will i need a complete sill?

Craig.

That looks like an expensive job to me. Certainly a lot worse than mine were. Your estimate is probably ok now that I can see how bad it is. Lord knows what they may find underneath that lot.

You could try Hadrian

They supply pattern parts but as you will probably cut it up to fit not so much of a problem