Most outlets consider up to two years old brand new.

You won’t get a tyre MOT advisory if there’s nothing wrong with the tyres. There is no ‘date’ MOT category for tyres, just damage/perishing etc.

Basically, if you ordered online for tyres and the guy turns up in his van and the tyre date is rubbish, don’t sign for them and reject them. Ditto if you get tyres fitted at a tyre place. Look at the date and if you don’t like it, say you don’t want them fitted.

Obviously give and take is involved, and what one person accepts another might not. I mean, it may not be the most ideal situation, but, as in the case of my Potenzas, two 3/4 of a years old and one 11 months (the other was 6 months) is hardly amazing, but a bit harsh to reject them. Not every ‘new tyre day’ is going to see one month old tyres fitted, unfortunately.

My original front S001s are 4819 and have also had the MOT advisory of cracking, again, on the tyre surface, not the sidewalls.

The car has been garaged since I bought it 18 months ago.

Pushing 5 years old I guess, and some mileage as well?

My original S001 has small ‘cracks’ in between the outer shoulder tread. Small ones perpendicular to the tyre direction. I asked a tyre fitter on spec, as well as mentioning it on a service, and to an MOT guy on an MOT day and they said they’re nothing.

29000

29K miles out of them? Where do people sign!!

![]() They are the fronts and are on the way tread wise. The dealer I bought the car from had put new tyres on the rear for the sale…Comforser CF700.

They are the fronts and are on the way tread wise. The dealer I bought the car from had put new tyres on the rear for the sale…Comforser CF700.

Never heard of that maker, or even any internet searches.

All booked for 4 new Kumho next week

from those pictures, they are done unfortunately.

It’s an advisory as you do need to change them in the near future.

Tyres need to be used to get the heat in them, get them all to temperature and the compounds doing what they do and keep the rubber supple. Standing around (and in tyre terms 10k miles in 4/5 years is a lot of standing round) which just perishes the rubber through lack of use and a lot of that was during lockdown so you really were not going very far, often - which did for a set of mine too.

Those tyres look pretty well shot to me. Once the tread depth gets down to 3mm the wet performance drops drastically even though the legal limit is 1.6mm. The cracks look very deep and if they were mine I would replace them immediately.

I put a set of Goodyear Eagle F1 Asymmetric 6 (215 45 R17) on my car and after about 10,000 miles they look really good and perform brilliantly even when pushing on pretty hard… They are also much quieter than the Asymmetric 5s (which I have fitted to my other car).

I chose the Goodyears because they came out top in the tyre review on YouTube and were available at a reasonable price.

In reality any premium tyre will perform well with only marginal differences between them driving on public roads.

My tyre guy replaced the tyres on my Hyundai Kona which I bought at two years old but with only 5k miles. There were whatever make Hyundai use -Hankook maybe? Anyway, I noticed shortly after buying the car that the ride was harsh and road roar noticeable . Even worse , wet grip was poor and even with diffs locked it was appalling on even wet grass . Even though they were almost unworn I changed to Goodyear Vector all season tyres and could hear and feel the difference within 50 yards , and off road grop was transformed .

And here’s the thing - Donald told me that my experience was very common in 2022 - because of what he called Covid tyres - tyres which had barely been driven on in the previous two years . A side effect was that such tyres are also absolute b****rds to remove from the wheel rim .

If they don’t look right, and/or feel right they are almost certainly not right - regardless of age .

I don’t necessarily agree with that. I’ve a car which had PS4 and they had small cracks in them after a year, 10K miles. I eventually got another 4K or so miles out of them. The SAME tyres bought again are on the same car, and 3 years on and only about 4.5K miles, and look as good as new. So no way lack of use has affected them.

Also, my ND’s Bridgestones had similar micro cracks between the tread shoulders when I first noticed them literally a year or so after I had it. I’d done about 7-8K miles. They never got any worse over the next 8 K miles, when I only used it about 1.5K miles a year.

disagree away, you’ll get away with it for a few years while they are still supple, but eventually standing about will get to them. Best thing with these cars is to use them, not just for the tyre health, but all the drive components and systems.

Apparently MOT centres are putting up advisories routinely…

Just going by my own experiences.

I should have probably added that when I do use a car which does, say 1.5K miles a year, the drives are okay, warming everything up, and not, say, lots of miles dowing driving to the shops 700m away out of laziness.

Helps with their DVLA stats if the fail a few ![]()

I see there is lots of knowledge here, so I thought I would add some.

First up, to allay fears, I have seen far worse and nobody died.

Technically, the rubber has lost some of it’s elasticity, and is particularly noticeable at the base of the tread void where the rubber is thinnest. This results in some tearing, it is not perishing, where the rubber is actually crumbling. It is quite common and I have seen it on tyres as young as 18 months. This area is subject to a lot of pneumatic load, from the air being compressed between the tread and, when it rains, hydraulic.

Iain is correct, it is quite common on infrequently used cars and after a very quick look at my scrap tyre pile, of the three sets that I could immediately see, two of those sets have come off MX-5’s.

Rubber like a bit of regular use to keep it supple. It’s disulphide bonds like a little stretch and a bit of gentle heat to keep them in working order, much like most of our backs. The environment where the car is kept can also have an influence, garages with heat can dry tyres and particularly tyres that are stored in centrally heated environments, so in the house, are prone to “drying out” quite rapidly.

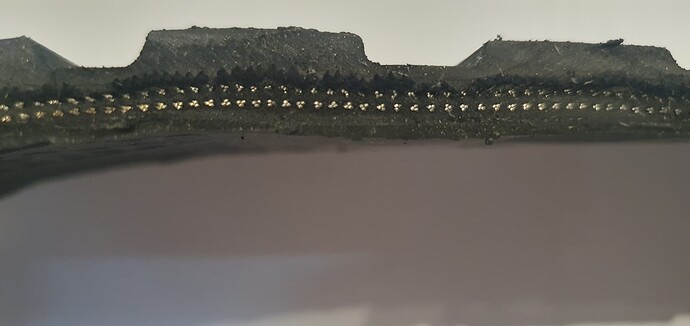

Any way, I have cut one up one of those tyres to show you the construction. It is a 205 45 R17, 88, so extra load tyre.

There is a bunch of pictures below. I am afraid I have no time to start annotating the pictures, so most of the writing is here.

Firstly there is a picture of a tyre that met a sad end. It is not the tyre in question, but it shows the construction well. Under the tread rubber is a fabric “Cap Ply” belt, which is a seamless cord running around the circumference. It reduces heat build up in the steel belts and so aids high speed running. Too much heat is the enemy of rubber. This sits on top, of the steel belts and those in turn on top of another fabric “Carcase Ply”. The steel belts, greatly aid the tyre keeping shape and the tread flat, and then the carcase ply also helping the tyre keep it’s shape. These layers are all calendared first and impregnated with the appropriate rubber, which has different functions to tread and sidewall rubber, so these belts or plies are separated from each other.

Then you can see the section of tyre. Tears typically start on the outer outer grooves and the shoulder flexes more. I washed this part, you can see the original tyre.

Then you can see the construction. The dark “fluffy” line is the cap ply. It has clear separation from the steel plies. You can see the tear on the left of this.

The next pictures show the tear, it is very much exaggerated because the tyre would not be opened up like this normally. I’ll point out again, this is a tear due to losing some elasticity, not the rubber crumbling. The very important bit however is that the tear is arrested at the cap ply. It cannot propagate beyond this without ripping the cap ply open, which is separate and different rubber to the harder tread rubber and it won’t do that.

It is a tearing of the thin tread rubber in the local area and not a general breakdown of the chemical structure of the tread or sidewall rubber compound.

Finally the video is to show just how little stiffness or resistance to folding a standard sidewall has, not a run flat which has a different construction in the bead area. There is no effort at all in bending this. The sidewall requires air to make it stiff. And it also shows that grossly under inflated tyres will flex and bend and that flexing causes heat due to internal friction in the rubber and can lead to the rubber breaking down and a potential blow out. It is also why if you have ever had a puncture and driven on, why there is a burning rubber smell when you stop and why it is not recommended that run flat tyres are repaired.

Finally, a word on date codes and age of tyres. Modern tyres use very few, if any of the old organic oil plasticisers that “boiled off” quickly in storage. In fact they are very stable, if stored correctly after manufacturing, and only start to age after the vulcanising process when the secondary heat cycles, from actually using them, come into play and the polymer chains are stretched and heated. Yes there is natural rubber in them which will age, but far more slowly than tyres used to. On top of which, tyres are not rattled out of machines at pace, they take around 25 minutes per tyre to manufacture, so even at full, uninterrupted production, there is less than 60 tyres per mould per 24 hours of production. While manufactures use multiple moulds and multiple machines, it still takes a significant amount of time to make volumes of tyres. So just within the same production run of tyres you can get significant date differences. Then, tyres are not made in “just the right number” because the set up times of machines and the shear number of different sizes and types of tyre mean that tyres are put into stock at the manufacturing plant awaiting an order or central warehouses. I was last at Bridgestone’s central European warehouse in 2007. At that time they were doubling their tyre holding capacity from 2.5 million to 5 million. Tyres are not made just for your car last week. Do not be afraid of a new tyre that is 3 years old when it arrives. It will be absolutely fine.

And finally, finally, I just thought I would do a hardness test on the cracked tyre and then in this order, a used Goodyear Asy6, a new Conti PS6, a new Conti SC7 and a new race tyre. Make of that as you will.

very helpful, thanks

What I should have done was taken a picture of my Bridgestone S001 tyres at the time of replacement, having done 5 successive years of low mileage of ~ 1.5K miles per year (after an initial year of 7k miles) , and shown that they had no cracks in the tread voids. Missed an opportunity there. So if such void cracks are allegedly ‘quite common’ on infrequently used cars, maybe that’s another reason to stick with the OEM ND 2L Potenzas ![]()

I have no personal experience of the S001, I had a set of S01 Pole Position some years ago and thought they were quite good, they were a dual rubber construction, quite narrow for the sizing though. The newer S001 has never shone particularly in any tests and I believe the tyre is now superseded by the Potenza Sport.

When engineers select tyres for cars, they will perform all sorts of tests on specific tyres and the tyre manufacturer will tweak the tyre to give it the characteristic’s that the car manufacturer wants, to then produce the OE tyre. The generic tyre name usually only denotes the tread pattern.

The predecessor to the S001 was the RE50A, and it came in more OE flavours than you could shake a stick at. It, however, was not an age friendly tyre.

One thing engineers can’t test for is cars sitting around doing nothing.

That’s what I’m here for.

I 've had these advisories a couple of times with our Roomster, which only does about 5,000 miles per year. My MoT man is pretty reasonable, but I don’t think it’s dangerous so I don’t rush to change them until it’s due another one, to save myself embarrassment!

I’ve never had a tyre fail other than through damage, including when as an impecunious youth I used Colway remoulds at £3 each.