In the heat of midday today (+31C outside), SWMBO comes into the cool living room and says “The washing machine is broken, and it’s full of washing.”

Our “laundry” is one of the hottest rooms in the house, +40C when I investigated, and yes, the motor was not doing anything, but everything else was working.

It can only be the brushes (£7 delivered next day) and I’ve lost count of how many machines I’ve done over the years, one of my school holiday jobs was fixing them.

It’s dead easy, back off the machine, slip the belt off, undo the two bolts holding the motor, ease it out and unplug the loom, remove motor and vacuum and replace the fiddly brushes in the cool of the workshop.

Dead easy in theory. And the carbon dust on the floor inside the machine is a big clue to the problem.

BUT, that motor was not budging, mind you it has not needed to budge in twelve years.

So while I thought about how to get it out I ordered the replacement brushes, and drank several ice-cold glasses of OJ.

After half an hour of melting despite having a fan on me while failing to move it, I decided to follow Ed China’s frequent option and make a custom puller. Tricky with not much room for access around the motor or between it and the drum, and I did not want to damage the plastic drum.

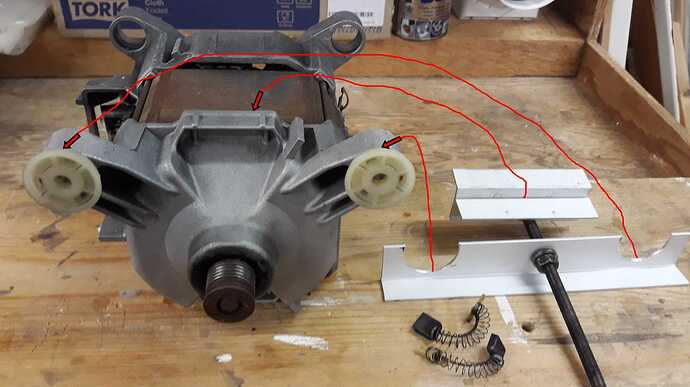

Eventually I found some studding, and some left-over ali angle in my scraps, and made the two halves of the “puller”, one strong enough to hook on a casting edge of the motor and braced to hold true, one to pull against the plastic of the rear motor mount on the drum but miss the motor inserts.

An hour of fettling later the tool finally fit securely.

One minute winding the motor out and I could unplug the lead and retreat to the cool of the garage. Two minutes later both very well worn brushes are on the workbench.

At last, time for a late lunch/afternoon tea back in the cool again.

The washing can wait.