I’ve been messing around with cars for a number of years and I’ve never changed a cambelt!?

There’s no better time than the present, so here goes my attempt. Knowing these engines are non-interference gives me a little more confidence, but I’ll be checking and re-checking everything.

Gates Cambelt & Tensioners

Gates Water Pump

Gates Drive Belts

Tensioner Spring

OEM Crankshaft Pulley Bolt

OEM Woodruff Key

OEM Thermostat & Gasket

Jass Performance Camshaft Locking Tool

I apologise if I miss any info/steps, this job did take longer than expected and my brain was frazzled by the end of it all.

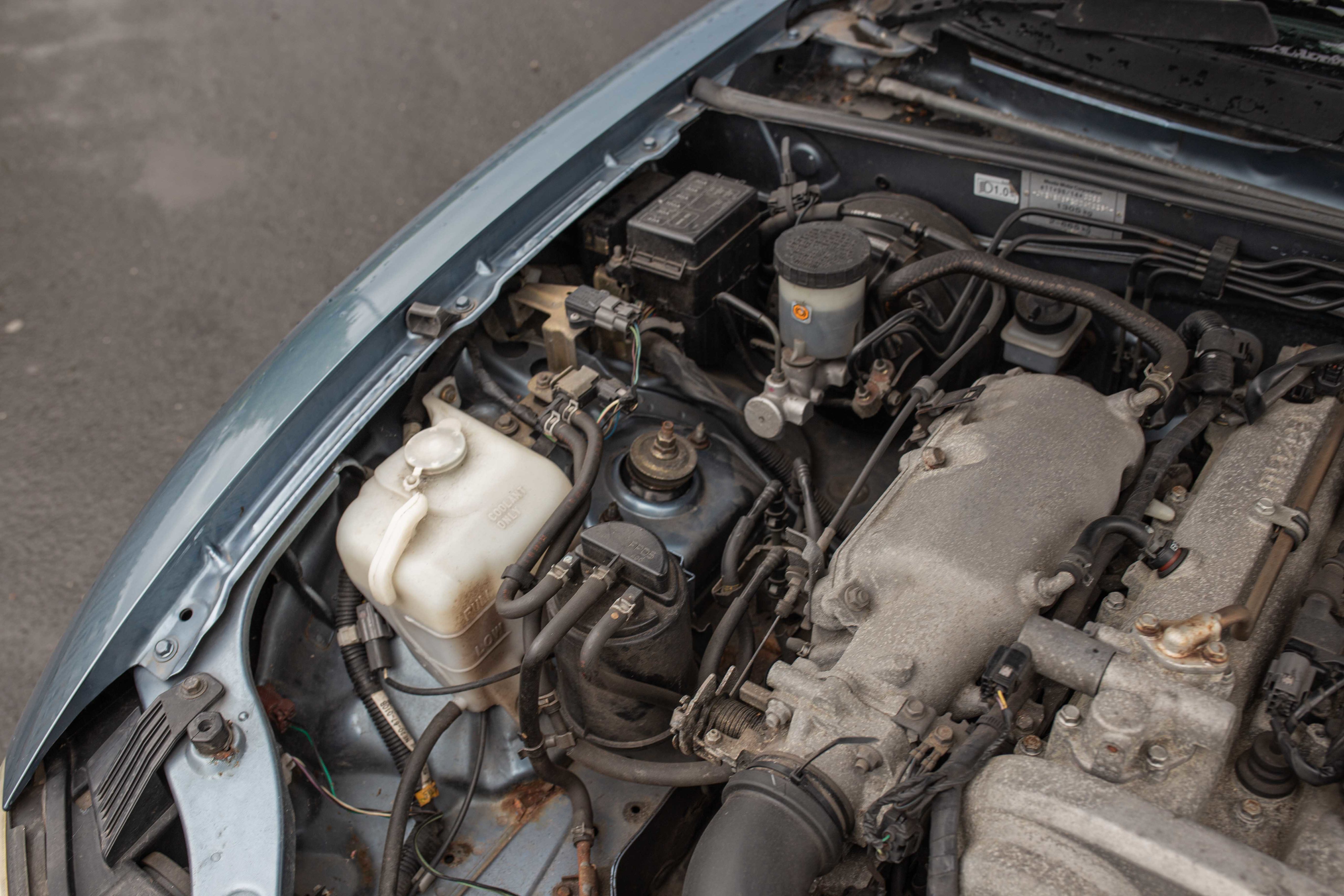

Starting off by removing the air intake pipe, unplugging the MAF and temperature sensor on the air box along with the crankcase breather pipe. I also unclipped the cable tidies to make as much space as possible.

Moving onto the drive belts, starting with the PAS and AC belts. ** Before doing this, slacken off the x3 10mm bolts on the waterpump pulley **

Moving the PAS pulley so the slot lines up with the bolt on the PAS pump. With that cracked off (making sure you use spanner or socket on the nut the other end of the bolt) you can crack off the tensioner bolts (I unwound the long bolt nearly all the way) . These are mainly 12mm and 14mm from memory. The bracket that holds the tensioner bolt, the bolt on the left nearest the waterpump will need undoing too.

The PAS pump should now push down, allowing the belt to slip off.

The Alternator is a similar job. There’s a 14mm bolt top and bottom that will need to be slackened. The bottom one in particular was an a** to do. I had to borrow a long spanner to do it, even then it didn’t want to move despite alot of Plus Gas penetrant. Once that was done the top tensioner bolt could be undone like the PAS. Once those were loose the Alternator will pivot to the left allowing the belt to be removed. The water pump pulley can now be removed too.

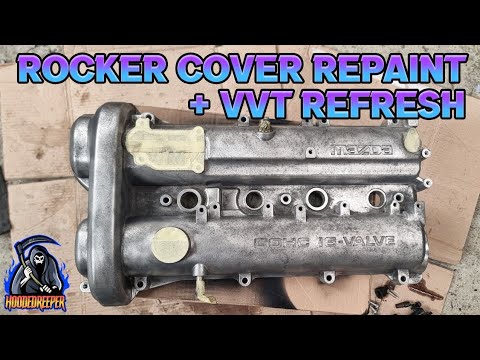

Next up was the rocker cover, from memory there’s x11 10mm bolts and x6 10mm bolts for the coilpacks/brackets. For the VVT I undone the 19mm banjo bolt and the feed pipe lifts off with the rocker cover. There’s a couple of plugs that’ll need unplugging and the PCV hose before lifting it up.

The radiator has to be drained and removed to allow better access to the crank pulley/harmonic dampener. You can either drain the coolant from the drain plug on the bottom of the radiator. Or you can remove the lower hose like I did. Make sure you have a container to catch the coolant.

Remove the x4 10mm bolts that hold the harmonic balancer to the face plate (you may need to use a spanner/socket on the crank bolt to stop it from moving). The pulley can be wiggled back and forth to release it. These can corrode and seize on so be careful. The face plate stayed attached to my pulley, some will split apart (hence removing the x4 bolts).

The next step is to move the wiring away from the front of the engine. Theres a few brackets and cable tidies but nothing too complicated.I moved mine away to the side and on top of the throttle body/inlet manifold.

The timing covers should now be accessable, the top has x1 10mm bolt in each corner. Once removed the cover can be pulled forward and upwards. The lower cover is split diagonally, some times called the middle/centre and lower covers. The middle cover is only held on by x1 bolt to the left. The lower cover has x3 bolts, one at the top near the waterpump and one either side towards the bottom. These are prone to cracking over time so be careful removing them. I do need to replace mine but I was unable to source replacements over the weekend.

With the car in 5th gear it’s time to undo the crank bolt. I used a deep 21mm socket on a breaker bar and it cracked off reasonably easy. It’s also advisable to remove the anti roll bar incase you wish to use an impact gun. My anti roll bar was left off from the coilover fitting so that was something I didn’t need to worry about. With the bolt undone, I rethreaded it into the crank so I can check the engine was in TDC.

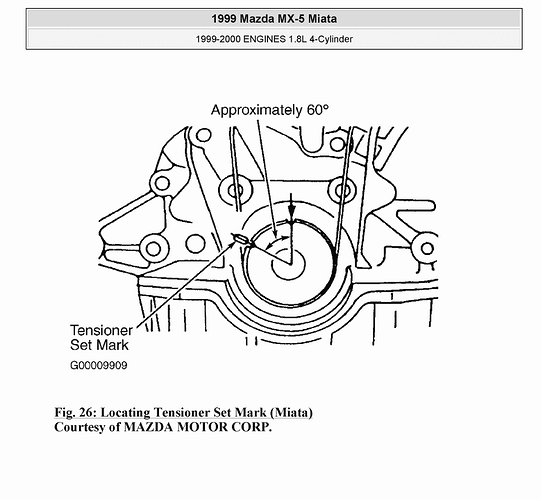

For some reason this was one step of the job I wasn’t too sure on, but infact it was very simple. With the spark plugs removed I could turn the engine over without any compression. The backing plate behind has two diagonal markings which need to line up with the notches on the camshaft pulleys. For the crankshaft pulley there’s also a notch which needs to line up with a V. Turn the crank bolt with the socket until all 3 markings line up. The engine is now in TDC (Top Dead Centre).

To stop the engine from moving/turning when removing/fitting the new belt you need to lock the camshafts. There’s a few different methods, the ‘old school’ way is to use a pair of spanners locked together with some locking grips. Another way is to use a tool that goes inbetween the two camshafts, which isn’t any use if the cam pulleys need to be removed. Luckily Jass Performance have developed a tool which goes over the hex sections of the camshafts, locking them together. This tool has two different sized ends depending on the engine. The VVT uses the larger size. With the tool slipped over the camshafts, tighten the two bolts and you’re good to go.

At this point of the job I wanted to replace the camshaft seals. Starting off with the exhaust side, the bolt was removed and the pulley wiggled off. I used a pick and carefully removed the old seal. Make sure you don’t score/damage the camshaft or block. Any damage will lead to a leak which you don’t want!

I purchased a couple of tools from Autolink UK which help fit the new seals. Unfortunately I don’t have a photo, but I’ve included it in the Youtube video.

For the VVT pulley there’s x3 torx bolts that hold a cover on. Behind this is the 17mm? bolt, with this removed the pulley slides off like the exhaust side. This seal is exactly the same procedure except it’s a slightly larger seal.