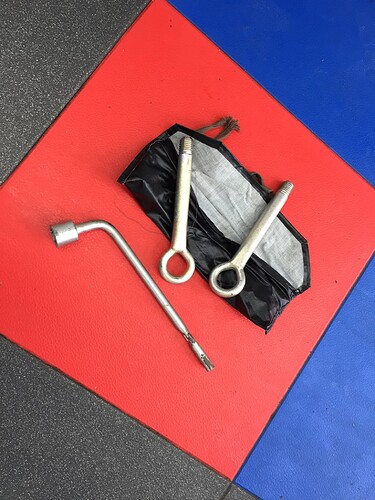

Hi, I have a 2013 Mk 3.75 but while preparing for my first track day I’ve found that neither of the towing eyes will screw into the front socket. I’ve taken the little plastic cover off and looking in the threads of the hole where it’s meant to screw in are a bit rusty but it doesn’t feel like the the towing eye is even starting to screw in - it almost feels like it’s just a bit too big and the threads aren’t even trying to engage.

The rear one is stiff but does at least screw in

I just wondered if there is more than one size towing eye for the NC? I’m going to try cleaning the threads as best I can (access isn’t great) but I’m not very hopeful - slightly concerned the track day people might be unhappy if I can’t fix it in time - not sure how seriously they take fitting a towing eye.

I can’t remember but I’ll ask the obvious question and you can tell me you’ve tried it but is it a reverse thread?

2 Likes

That’s a good shout but it doesn’t appear to be, I’ve tried both directions with the same lack of purchase. The rear one does screw in clockwise so I’m assuming it would be the same at the front.

Put your location, it may help

I have spares

1 Like

It’s just rusted up. You can either apply some lube and wind it in (once it bites put a bar through it to turn it) or get a tap and clean it out.

It’s a common problem and I’ve done so many I have a tap, it’s M20 x 2.5.

If you have a small engineering company nearby you could ask them, but it’s a rare size so they probably won’t.

Edited for accuracy.

4 Likes

If you haven’t already, you may need to remove the shiny plastic panel in addition to the “plug” in the bumper cover. Otherwise the angle isn’t right. Caught me out first time.

1 Like

if you can put a tow eye on the back its fine.

If you cant put one they may ask you to sign a disclaimer that if you come off they will use whatever means necessary to take the car out - even if that means dragging the car from the wishbone etc. Ask if this is the case if you cant fix it.

it probably rusted up as already suggested (although the front is somewhat more protested than the rear from all the gunk). personally I’d expect the rear to be the one that goes first.

Personally I’d spray wd40 on both sides and try to fit the tow eye in.

Thanks for all the suggestions, I’ve got hold of a wire cylinder brush now and will have a go at cleaning some of the rust off - maybe that along with some lubrication will get it sorted. Failing that I’ll need to look at the re-tapping route.

Also good to know it’s probably not a deal breaker for the forthcoming track day - will still try and fix it beforehand though.

I made a “tap” out of a spare towing eyelet by cutting (with a grinding disc) some groves down the threaded part.

1 Like

I understand it is important to have the tow hook mounted (front and rear), as you may need a hand if you spin outside of track or have a breakdown, but if you can’t mount it for now, before your Bedford track day, it doesn’t mean you will be prevented from getting to the track AND from advising the tow truck on where to place the hook in case you need to be pulled.

1 Like

Glad I read this post as both front and rear were rusted up and basically useless.

All sorted with a bit of patience and lube.

Will make that as part of my annual service too.

Thanks for posting.

With a suitable diameter wire pipe brush, elbow grease and lubricant the rear one is now nice and smooth, the front however remains a problem and despite all my efforts still refuses to engage with the threads.

I guess I need to look at re-tapping it - time to google what that’s all about as it’s new to me.

I’m anticipating the same problem. Some say that the front eye is at a funny angle in relation to the plastic hole - unlike the rear which is straight on. That could be why you are finding it difficult to engage it.

Another quote I read " I reckon it’s an M20 with 2.5 pitch. Given how expensive they are I’ll be looking for someone who has one and to pay him £10 to do the job."

Buy the cheapest tap you can find (Ebay). For this job you won’t need a tap wrench, simply use a spanner to turn it.

The tap will leave the thread a bit baggy so don’t go all the way in with it. Go in a bit then test it with the eye bolt, then do a bit more if necessary. You need to aim for the eye to lock up just as it’s getting to full thread depth.

Robbies method is also sound if you have the tools to hand and saves the cost of a tap.

Thanks for the advice. I do have a spare eye (somehow I’ve ended up with three) so maybe I’ll try that first before shelling out, and I guess at least it guarantees the correct size/thread.

If I were to buy a tap am I looking at something like: M20 x 2.5mm Hand Taps ?

Yes. Cheap as chips too, the 1st cut would be best, but in reality any would do it.

You could always try some kind of pass around with other club members, but at that price it hardly seems worth it.

I’ve ordered the 1st cut hand tap and will give it a go - as I always say if a job’s worth doing it’s worth getting a new tool for

1 Like

Did the tap sort the thread out?

1 Like

It did thanks, just managed to get to it yesterday. What I found was while the threads were all crusted up the threaded socket itself also seems to be pointing very slightly down - it’s a real struggle to get the towing eye in unless I take the trim piece below the socket off, if I do that then it now screws in perfectly.

Bit concerned popping that trim off and on will eventually break it but I guess that depends how many track days I do - could always trim a little off the top of it I guess for better clearance…

1 Like

Is that down from engine to bumper?