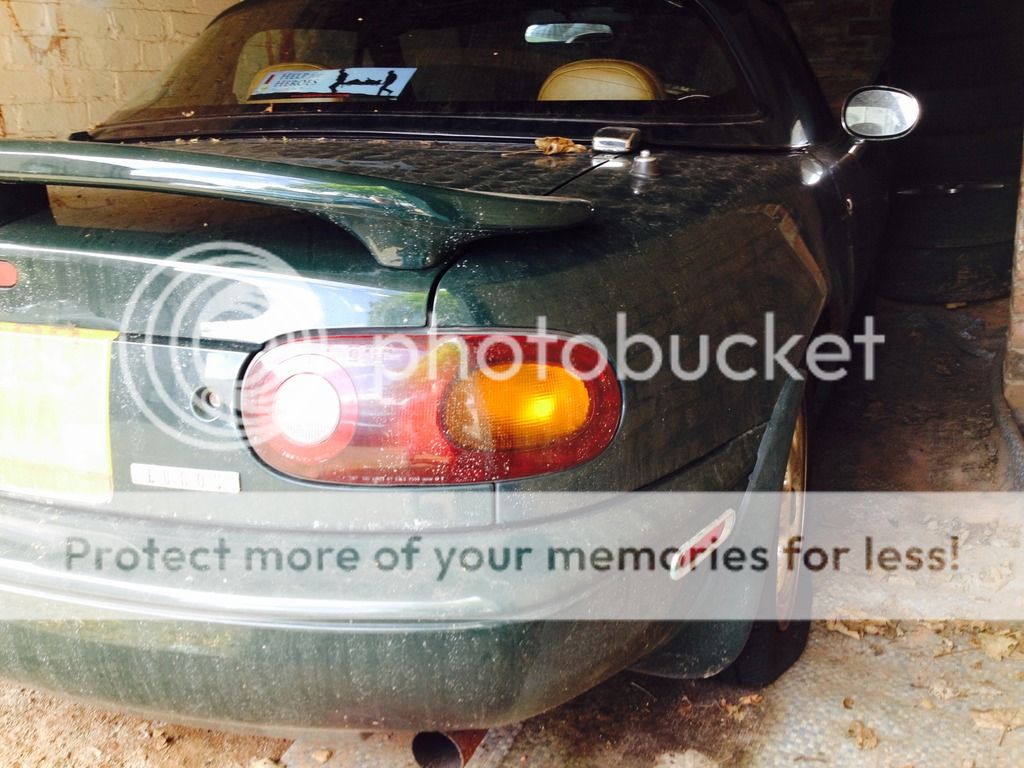

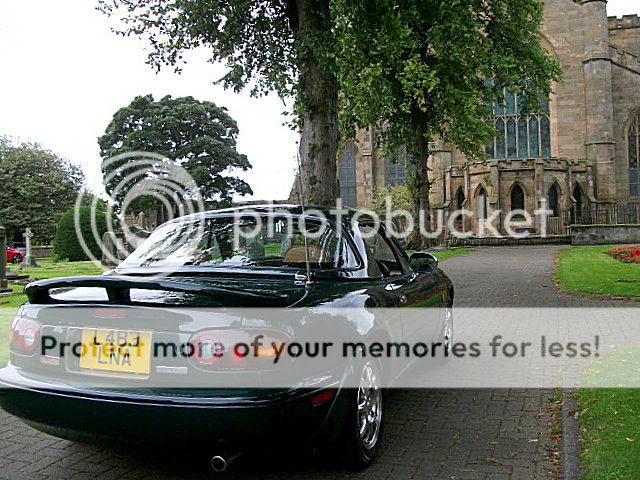

First off, I’ve never owned any of the 2nd generation iterations. Secondly I’m not a qualified car engineer. Right, with that out of the way, I’d like to know about the chassis rail repairs that have become very popular on these cars. My understanding is the original rails are thinner metal but double skinned, acting as a crumple zone in the event of a collision, absorbing a lot of the energy from an impact thus protecting occupants of the car. So, from what I see and hear about the repairs being undertaken, it’s the double skinned sections that get water in between and eventually, corrosion renders them dangerous. Which is a real shame as many cars have been scrapped when they are (look) excellent cars in other areas. The solution appears to be, welding in new sections of metal after cutting out the rot, using single skin metalwork. Sometimes prefabricated sections, sometimes made up metalwork in the shop.

My question (or point) is, these repaired sections are not the same as the original design i.e. single skin instead of double skin. Therefore, the original design of having a crumple zone in the chassis rails has been lost due to a dissimilarity between repaired sections and the original metal left in place. Was the original design brought about by ever more stringent legislation on car safety, I think it was. Are the repairs currently being undertaken, compromising this design? I think they are. These are only my thoughts put down in writing, not based on car engineering expertise.

Having prised the lid off the worm can, am I overthinking this or do I have a valid point? I realise unrepaired cars are getting MOT’s due to the rotten sections not being easily seen due to the undertray obscuring this, also repaired cars are doing the same.

Barrie