Thanks Chris! I only recant the success stories though  plenty of disasters along the way! TBH though, I don’t do too bad for a tinkerer!

plenty of disasters along the way! TBH though, I don’t do too bad for a tinkerer!

had some great advice and support off here too which helps enormously:+1:

Barrie

Well, I’ve ‘sort of’ got to the bottom of the skipping/jumping towards the end of an album. The spring loaded plunger for the tone arm lifter Has a screw adjuster built in which is accessible from the top. This fine tunes the lift of the tone arm, also dictating the down position when playing a record. Regardless of how accurate the tracking force etc is applied, if the setting on the lifter is too high, the tone arm cannot rest freely on the record grooves. It rests on the lifter curved rail if any of that makes sense?

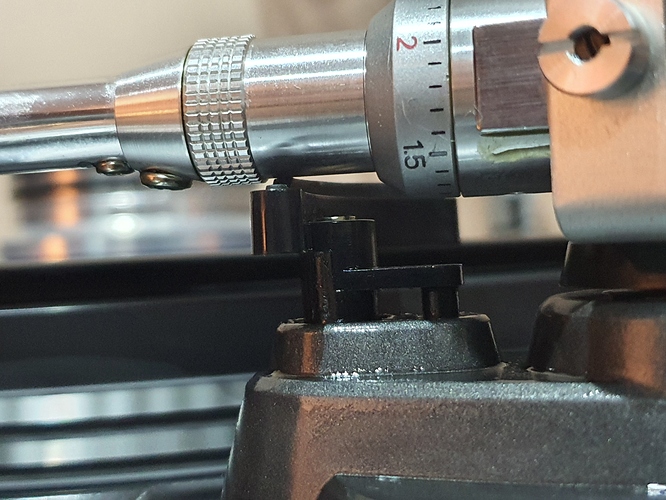

Picture here, the adjustment screw is in the middle of the picture.

Not got it 100% right yet but much better! The plunger/lifter arrangement is a little stiff in its action so doesn’t always drop sufficiently to clear the underside of the tone arm, keeping the tone arm from floating freely onto the surface of the record.

This pic shows the lifter I contact with the underside of the tone arm,

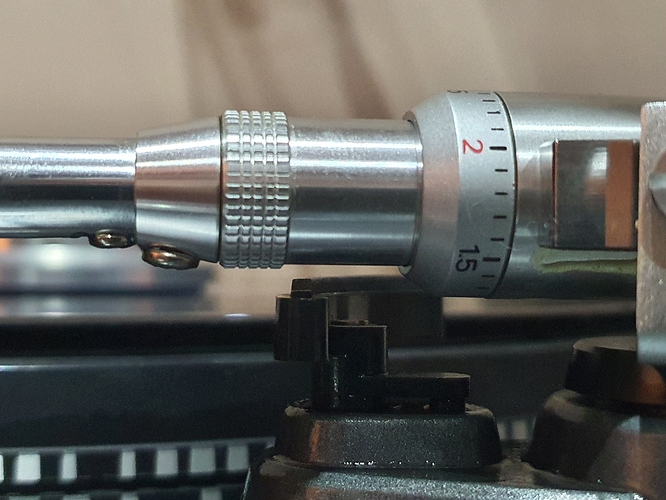

This image shows the free gap when in the ‘play’ position,

So, in conclusion, I managed 3 out of 4 sides of a Frank Sinatra double album with the auto return functioning perfectly, one side jammed up slightly so had to help the plunger to seat fully down. This then worked correctly

Getting there!

Barrie

Excellent job.

I had a look at the circuit in the manual and these are simply wired in series with their respective thumb-wheels. They are the correct ones to adjust.

Your photos help a lot! It is almost like being there.

If you had adjusted VR03 or VR04 these are the DC offset adjustment for the motor drivers, and not a good idea if you don’t have a 'scope for easy correct setting for a symmetrical waveform around 0V.

However, if micro-switch S5 is closed (return position) and it has disabled the Hall commutator elements (because the arm and motor are parked), then they set the zero volts through the motor coils (blue and red wires relative to black wire). But you might need to fiddle the turntable position to find the right zero.

I assume R17 under the bundle of wires is not 2.2K (as shown on the circuit) but also 2.2M (red, red, green, silver) the same as R20. If 2K2 then the adjustment will be a fiddly over-sensitive nightmare.

If the motor is getting hot when parked, and one of the four transistors is also getting hot, then VR03 or VR04 is wrong; two trannies hot then both pots wrong!

VR05 sets the power balance between the coils, imbalance will cause flutter. It actually matches the signal from the Hall elements in the motor to the drive in the coils, and needs to be set with a flutter meter and the test record.

Thanks for confirming that Richard! I now feel like the guy trying to save the world, disarming a massive bomb by cutting the right wire! Would have been a coin toss whether I’d gone for VR03 and VR04 instead!

Truthfully though, I’d vaguely remembered a post on a HIFI site a long while back (which I couldn’t find again) talking about these pots on this particular TT, bad though my memory is, it served me well today! I like pictures too, it just helps to make the posts slightly more entertaining

Barrie

See the manual I linked to in my previous post, it covers this specific adjustment, with measurements!

Thank you Richard, I’ve downloaded a copy!

Barrie

Yesterday I cutn’t spell enjuneer, now I is one.

well funnily enough, I am an Engineer by profession though retired now, also civil rather than electrical!

well funnily enough, I am an Engineer by profession though retired now, also civil rather than electrical!

Barrie

We were all engineers at BT. None of us really civil by any definition.

Anyway, moving on, the issue with my TT appears to have resolved itself without dismantling again. The plunger/lifter was a bit sticky and not descending fully on its own, as previously mentioned. I applied contact cleaner to those parts while I had it in bits yesterday. This appears to have cleared any old grease, dust, debris etc and it now descends smoothly and more importantly, fully, allowing the tone arm to work correctly. Can’t seem to find out whether the mech should be lubricated in any way though  might get some TT spindle bearing oil which is very light and apply a drop to the plunger.

might get some TT spindle bearing oil which is very light and apply a drop to the plunger.

Barrie

A thin oil with no volatiles, sold for much the same price as printer ink.

At work in one of the theatres we had a big flat-bed eight-transport 16mm tape machine; to service underneath it were hydraulic rams to lift the combined quarter of a ton of deck plate. We found its thin hydraulic oil (which got everywhere) was an excellent lubricant for things like small motors and turntables.

However if you want an even finer oil go for clock and watch oil, again no volatiles so it will never turn to glue. We used an oil very much like this at our other sites, where we also repaired film cameras.

Avoid Singer sewing machine oil!

Thanks again Richard  will have a search and see what I can get.

will have a search and see what I can get.

Barrie

Just had notification that my new Audio-Technica TT will arrive on Monday  so just a week from ordering, thats not bad to say it wasn’t in stock

so just a week from ordering, thats not bad to say it wasn’t in stock

I sneaked my Tannoy Eclipse floorstanders into the lounge but Mrs B has noticed them!  short lived and will be going back upstairs soon though!

short lived and will be going back upstairs soon though!

Barrie

Further to Richardfx’s link to the AIWA AP-2200 service manual, I’ve found a copy of the original owners manual/handbook! Already read a couple of pointers which I’m going to try out. One being the stylus overhang measurement, measured from the rear of the headshell rather than using the overhang gauge. Might be the same as I have it set but worth checking! Also setting the height of stylus above the record surface using the top adjustment screw mentioned previously, the OEM 45rpm adapter comes into play here as a height gauge! Fortunately, my deck has the original adapter which sits astride the tone arm rest  All worth doing to ‘optimise’ the turntables performance I reckon

All worth doing to ‘optimise’ the turntables performance I reckon

Barrie

Morning all, my new TT arrived a day early on Sunday! TBH, I was not even there to receive it as I was busy collecting eldest lads car to get it ready for MOT. Anyway, busy yesterday as well, working on his car, so this morning before I starting toget dirty with oil and grease, I thought I’d unbox and set it up. So a few pics of unboxing first.

This little fellow escaped initially as it wasn’t with the other ‘bits’ as such. It had been packed in one of the white boxes holding cables etc.

Easy set up of the TT and the speeds appear rock steady

a couple of immediate issues though, the tone arm, if lifted with cueing lever, instead of it just staying in the same position, moves back a bit toward the rest position. You can’t then rejoin the record at the same point. Might be anti skate needs more looking at although set to #2 same as tracking weight of cartridge. Second issue is a slight resonance? Tried it with lid down and with it removed. Also swapped out the supplied felt platter mat for a rubber one. Still slightly there

a couple of immediate issues though, the tone arm, if lifted with cueing lever, instead of it just staying in the same position, moves back a bit toward the rest position. You can’t then rejoin the record at the same point. Might be anti skate needs more looking at although set to #2 same as tracking weight of cartridge. Second issue is a slight resonance? Tried it with lid down and with it removed. Also swapped out the supplied felt platter mat for a rubber one. Still slightly there  the platter itself ‘rings’ when tapped so I might try some accoustic damping sheet I have left over from the 5!! Won’t be today though, got to get on with the lads car, MOT booked for the morning!

the platter itself ‘rings’ when tapped so I might try some accoustic damping sheet I have left over from the 5!! Won’t be today though, got to get on with the lads car, MOT booked for the morning!

Barrie

Barrie, just a thought. The bias adjustment on my SME p/u arm (with the 401) relates to the weight of the Shure cartridge, not the tracking weight of the stylus because they were all independent units. The p/u arm on the Rega integrated t/t/-p/u-cartridge the bias is based on the tracking weight the same as your Audio Technics set-up, because it comes supplied with a cartridge, probably because the weight of the cartridge is taken into account when factory fitted/OE. Have another look at your handbook, that MAY be the answer.

Thanks Roger, its meant be the same value as the tracking force, in the case, 2. I’ve not really had chance to look properly yet but I do have a tracking force gm scale so will weigh it and see how it compares to the setting on the counterweight. Its quite possibly a mile out!  I don’t have a plain sided record to set the anti skate properly either, so might invest on an acrylic TT platter to check it more accurately.

I don’t have a plain sided record to set the anti skate properly either, so might invest on an acrylic TT platter to check it more accurately.

Barrie

Back in the distant past when I had lots of thick, thick under-seal to hand for getting dodgy repairs through MOT, I found it was also very effective at removing the ‘ting’ from work turntables without unduly affecting the balance.

The trick was to support the rim-drive TT (usually 301 or 401) upside down in a suitable pivot assembly and slowly spin it round while applying gloop with a soft brush for an even distribution. It didn’t need much at all.

We only did this because of the cueing method where the needle sat less than a quarter turn from the sound-effect needed for play in, and there was a protruding felt disc ‘brake’ between TT and mat. The metallic ‘ting’ was excited by the felt rubbing on the rotating TT while the record was stationary because of the felt being held and could be heard through the stylus.

Memories!

Thanks Richard, I did wonder about balance. The platter spins very true and speed (going by the strobe) is very consistent. Just this slight resonance. The other thing, although playing the AIWA TT was fine, is the small Mourdant Short bookshelf speakers lack bass so may be highlighting the issue. They are mounted on acrylic corner shelves at the moment which were installed for much lighter 4.1 surround from the Phillips Fidelio B5. When i get time i’ll explore it more fully!

Barrie

Ah, you don’t want to be involved in modifying them! The effort involved is just not worth it.

But you can find out what they are actually doing relatively cheaply. They might need to be buried in among books. (The name is the clue.)

It took me a week of measurements and experimentation to fine-tune my Edifiers ending up with new bass drivers, and it was only possible because I have some suitable (very, very rudimentary) test gear and have done it before professionally.

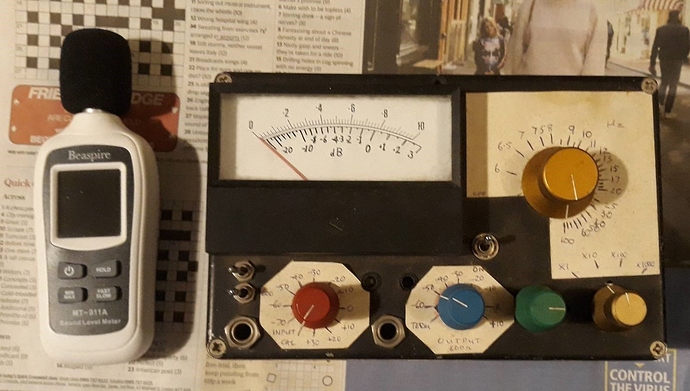

The black box with the tone-source and audio millivolt-meter I made in the late 1970s, and it still works.

The cheap-looking sound-level meter was a freebie from Amazon and I tested it against some very flat hifi professional mics and it is surprisingly good in the bass and midrange, certainly good enough for speaker testing, but it is lacking above 8KHz. Others exist, probably clones out of the same oriental factory.