I just want ask all of the ND owner that have hand their 5 up on axle stands, where did you jack from and where did you place your stands? Can find no straight answers from anyone, not even the dealers…

V important to avoid the rust-weakened areas.

double posting.

If my ND was already rusting I would be having some angry words with mazda ![]()

Jack on the crossmember below the diff and centre of front crossmember, axle stands on sills in between drainage points. Is it not shown in the Owners Manual?

Jack on the diff and centre of front crossmember, axle stands on sills in between drainage points. Same as all other MX-5s. Is it not shown in the Owners Manual?

Nothing in the manual about jacking the car up at all, not even a scissor jack included in the breakdown kit. Just the gel and compressor set-up. To put any load on the sills I would need to remove the side skirts as the plastic covers them. The rear diff is reasonable but accessing the front subframe seems to require removing the sump guard.

I’ll get some pictures posted up tomorrow.

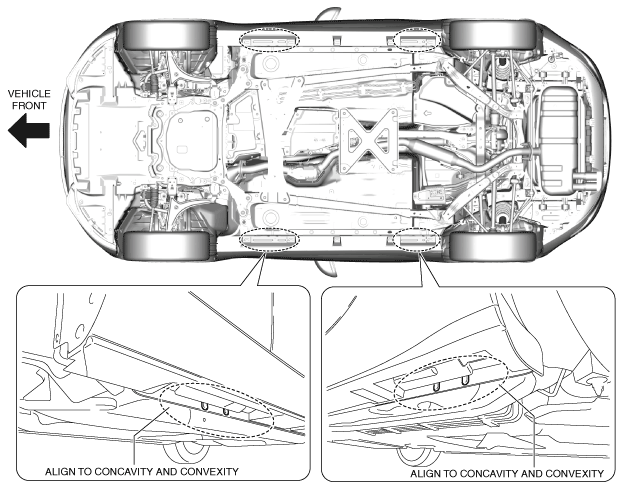

You need to come inboard of the plastic side undertrays and due to the car being low it is hard to see the metal flange and also there is not much room as the plastic undertray is very close.

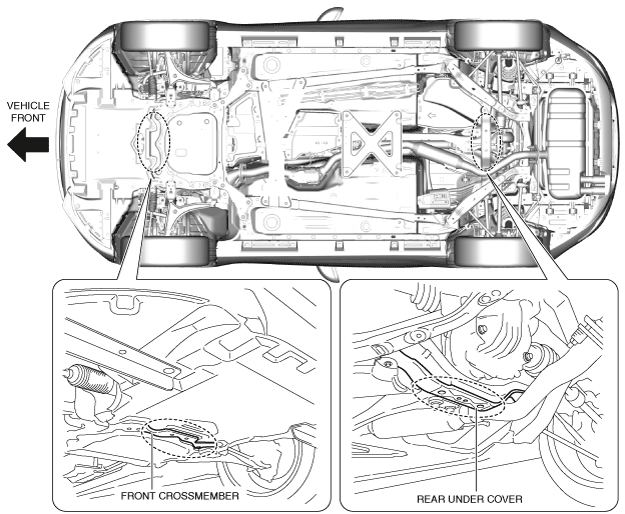

I have a two post ramp therefore I lift straigh from these points in the pictures that you would put the stands after jacking up the diff and front cross member.

This picture is better at showing the flange and you may want to get rubber pads for your axle stands.

Another view

Images from Mazda.

Jacking points.

Mazda don’t specify a place for axle stands they just say to use them after the vehicle has been lifted. I’d use the vehicle lift up positions as below.

Absolutely brilliant guys thanks, got both real pictures and diagram, couldn’t have asked for more! No idea where you got those diagrams though, I couldn’t get anything out of them!

Good diagrams for positioning axle stands after lifting, but I don’t understand the “align to concavity and convexity” comment at the lifting points.

There are two small “dimple” positions inboard of the wheels on what might be reinforced strips just inside the plastic sill trims.

Am I right to assume I position the scissor jack slot between these "dimples?

Yes, do that. It’s where the second picture shows isn’t it?

Yes they seem to be although the jacking flange looked quite thin and liable to distort if a flat rubber pad used.

Use a flat rubber pad on my NC and has not distorted the metal at all, heck I have jacked and put axle stands on the same sill area without issue.

Reaching the front subframe is a pain for me on the lowered car, I know I could drive on to wood and then do it, but by the time I have done that I could have had it jacked up and probably done one side at a time (instead of moving front to rear).

I can confirm the sill jacking points are solid, changed my alloys yesterday without issue on my ND.

These replies make me happier about the flanges for jacking.

OK, time for a thread resurrection…

I have studied the pictures in the manual for jacking points, but I’m still not happy with the placement of axle stands.

The recommendations for using the pinch welds don’t seem quite right to me.

If you look at the shape of the OE jack head (on my old Mk1 at least, not sure the ND even comes with a jack), then the pinch weld locates into a slot, but it appears the actual weight is carried by the flat surface that mates to the chassis just inside the pinch weld.

If you lower the pinch weld directly on to an axle stand, there is some significant sideways force applied as the vehicle settles and I worry this could bend the whole structure. I have certainly seen this on my other cars that have been up on garage lifts and had the pinch welds mangled. Maybe the MX5 ones are suitably strengthened, but you still have 250kg resting on an area of less than 5mm x 50mm.

At the very least it crushes and cracks the paint leading to rust ingress. This was certainly a problem on my Mk1.

An idea from Miata.net is to arrange the head of the axle stand on the reinforced area just inside the weld:

But that still doesn’t accommodate the saddle shape of the stand head.

A picture of a ND on a garage lift from Flyin Miata shows quite different placement of the lift pads:

They don’t use the pinch welds at all, which seems to be logical if you want to avoid any damage to the plastic side skirts/mouldings that are in close proximity.

I am think of buying some rubber pads off ebay that convert my axle stands to a flat top surface (like the garage lift pads), but where should they be positioned to safely support the weight of the car?

Bought a set of these axle stand pads off the bay. Machined from hard rubber hockey pucks.

We shall see if it is feasible to slot them to accommodate the pinch weld.