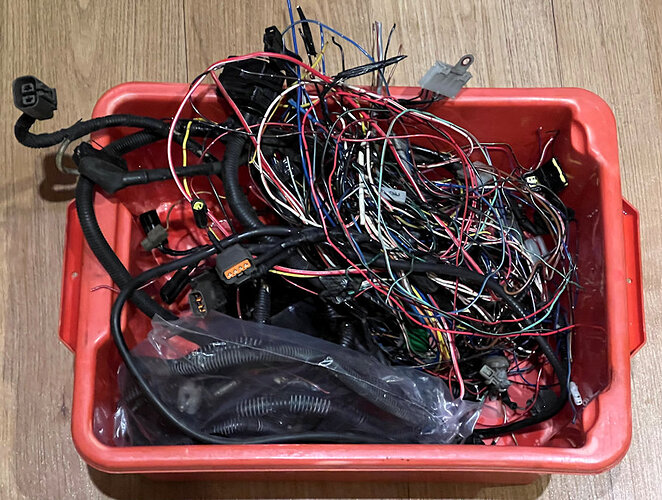

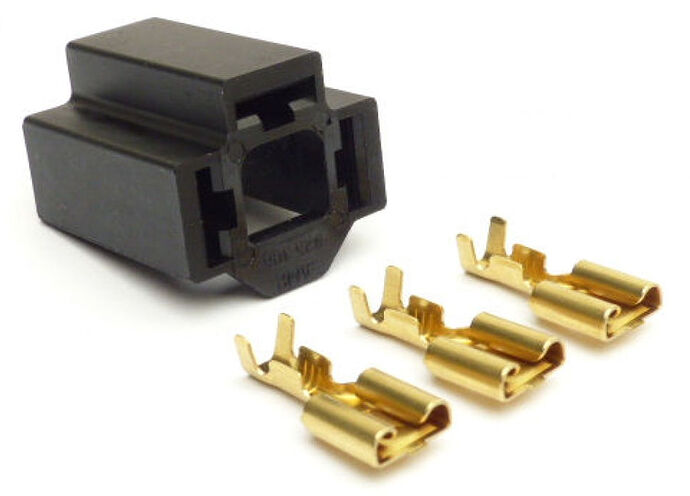

The connector kit arrived from EV Create today for the iBooster. We have chopped the old wiring loom out with bolt croppers and we are re-wiring the whole car from scratch. It’s just going to be easier this way and will result in a wiring loom that is much lighter and only has wires for the things we need. We are also adding a CAN Bus for a lot of the electrics/electronics, including the TPMS, VCU, inverter, iBooster, etc.

Spent a lot of time in Somerset sorting out my later fathers stuff but we are still making progress ! ![]()

Having spent a lot of time on the M4/M5 in poor weather, I decided that a black car is not such a good idea. We are now going to respray the car in McLaren’s Aurora Blue.

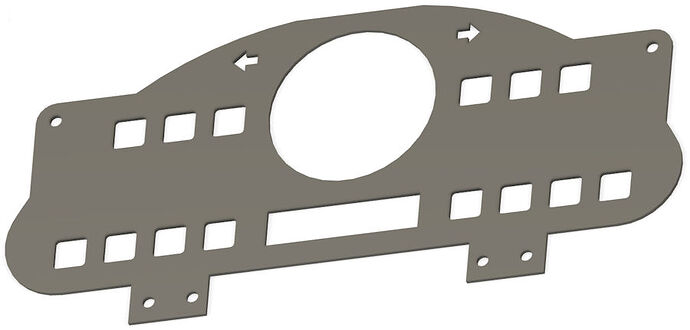

We 3D printed a template for the gear shift blanking plate and this is going to be used as a cutting/drilling template for one made from 3mm aluminium plate. We still haven’t decided where the FNR selector is going but, it might sit on this plate. This covers a large round hole into the centre tunnel.

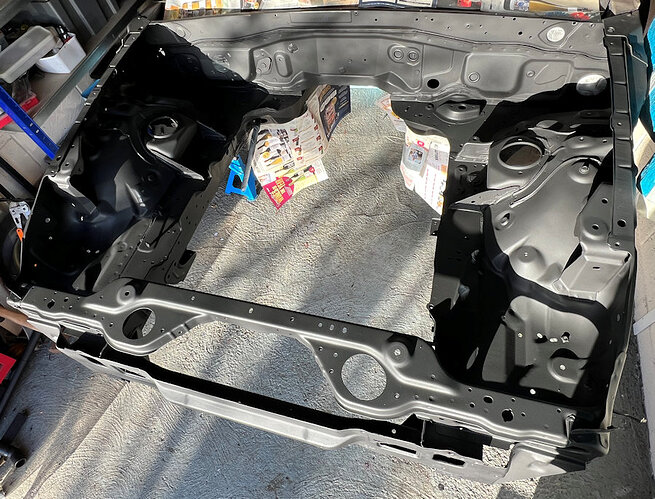

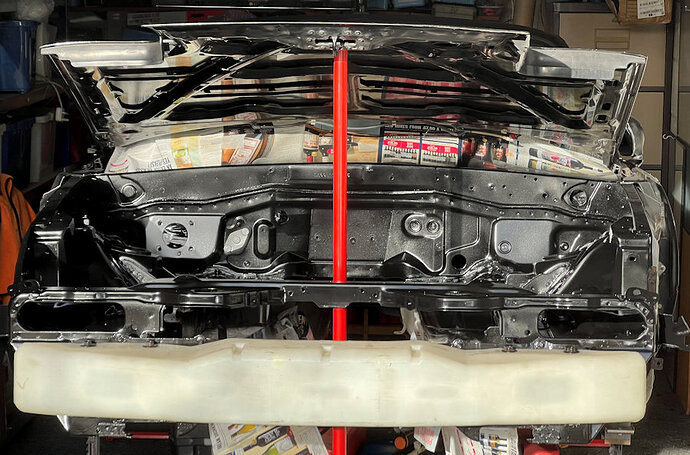

We have started masking and priming the engine bay. The wheel arch liners and wings will come off next, so we can completely respray the engine bay.

Some other good news is that our fixed reduction gear box will be shipping from the USA soon. More on this when it arrives and I can take pictures.

She looks sharp ![]()

We started on the wiring loom today. We took the decision to completely rewire our MX-5e when we took bolt croppers to the wiring in the engine bay. This was stripped down today and this is the 4kg of redundant wiring we have removed (just from the engine bay). The only bits we are re-using are the connectors for the lights, pop-ups, washer bottle and windscreen wipers. We are adding a CAN bus and fabricating a bespoke light-weight loom for the rest. We are moving the 12V battery (which will be a light-weight race battery as it does much less work in an EV) into the engine bay to help save even more weight, by keeping the length of wires shorter ![]()

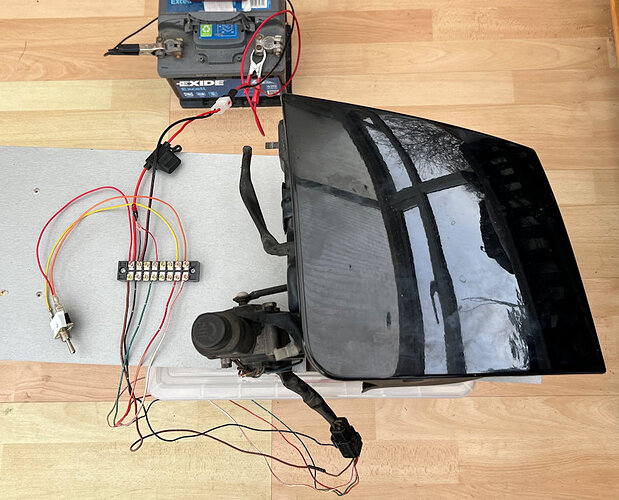

Having reverse engineered the wiring on our Eunos, we built this simple test rig to check our understanding os the pop-up headlight actuators is correct. It all went well and these will be smartly and independently controlled by the MX-5e’s DCU. We plan to have a wink button on the dash ![]()

The MX-5e display project is progressing nicely. We have the small OLED display working and displaying stuff in the right format. OSSEV - Digital Instrument Display Project

The engine bay is ready to be put back together now ![]() The new subframe, suspension, steering rack, ARB, etc will go in and then we can trial fit the Nissan Leaf motor. I’m very sure we will have to remotely mount the inverter to mount the motor deep inside the centre tunnel but, this is planned for. The battery pack will sit on the subframe using the engine mounting points and another frame that connects to the aluminium brace back to the differential.

The new subframe, suspension, steering rack, ARB, etc will go in and then we can trial fit the Nissan Leaf motor. I’m very sure we will have to remotely mount the inverter to mount the motor deep inside the centre tunnel but, this is planned for. The battery pack will sit on the subframe using the engine mounting points and another frame that connects to the aluminium brace back to the differential.

All very exciting.

Quick question…do all electric vehicle motors behave in the same manner?

Setting performance figures aside do they all exhibit similar characteristics?

I don’t know about anyone else but I’m old enough to still have the mindset of ‘If it’s got a rev counter it’s a bit sporty’.

Now I know that with an electric car there’s no gearbox or clutch so a rev counter would just mirror the speedo needle movement so it would be of zero practical use. I’d still like a rev counter just for fun but with a digital speedo in the middle.

What sort of revs will the motor be doing at 70mph?

Electric motors can produce the same torque at all speeds from zero upwards. Torque is limited by maximum current and power by voltage and heat dissipation (and the design of the motor, i.e. magnets and copper)

Car electric transmissions are designed to produce very high torque at zero speed, which can remain constant as speed increases until the maximum voltage is reached, then the power remains constant as speed increases further, so the torque reduces inversely.

As cooling will be affected by outside temperature and energy used to turn fans, max power is less in the summer.

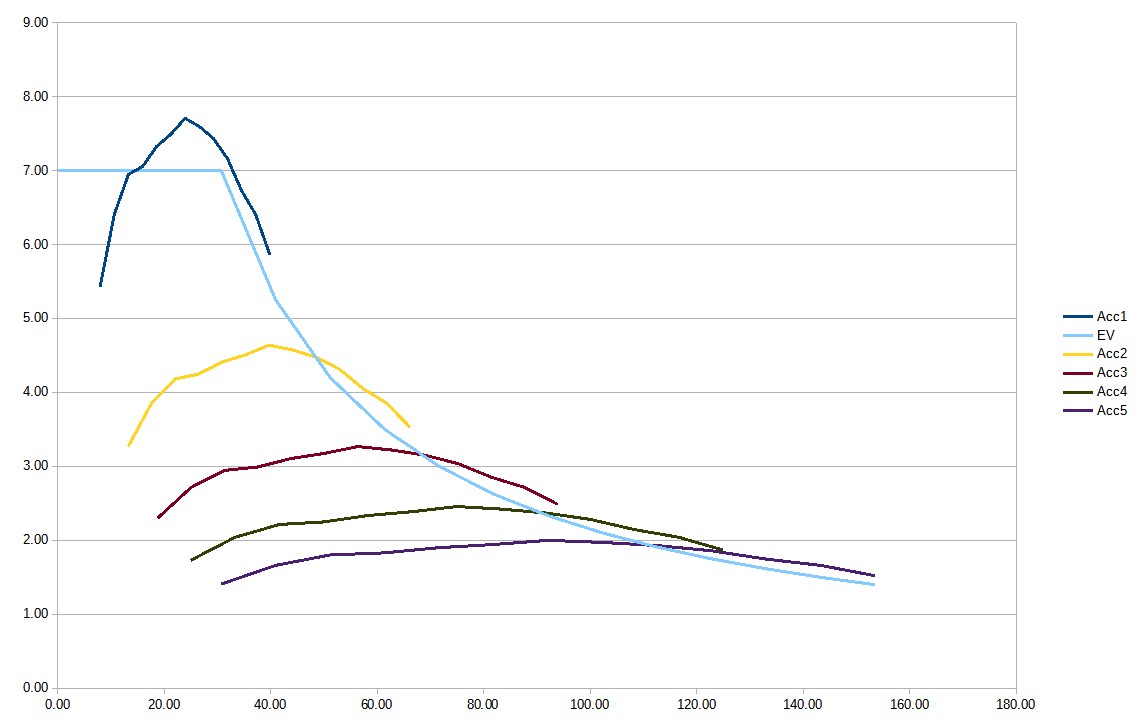

The plot shows the rear wheel torque for a NC1 2 litre plotted against road speed, with an imagined EV car curve overplotted, showing that the available torque/power can be very similar, i.e. and EV acceleration would seem very similar to an ICE with an automatic gearbox.

The Nissan Leaf motor I’m using spins at 10,600rpm but has a 1.8:1 reduction gearbox before it connects to the rear differential. The transmission design is described here: Open-Source Sports Electric Vehicle (OSSEV) - Transmission

Top speed should be about 109mph with our chosen transmission design and closer to 115mph if we upgrade the inverter. I predict a 0-60mph time around 5 seconds.

The Nissan Leaf motor is about 165bhp in basic form but we have upgrades planned to get to 215bhp. Torque is 350Nm but can also be upgraded to 400Nm. It will be a lot quicker than the MX-5 1.6 engine was, with full torque delivery from almost standstill, even in base form. As an EV is will also be a lighter car.

Displaying revs is a bit pointless as it has a linear relationship and there is a direct physical connection from motor to wheels.

You may need to upgrade to the 1.8 differential. The 1.6 is 6 inches, the 1.8 is 7 inches. The torque limit is around 200lbft

(270nm). How to keep your Turbo MX-5 / Miata Alive | Mazda MX-5 Performance Parts | BOFI Racing

I think it’s covered - “We have a new Super Fuji 3.6:1 ratio LSD for the MX-5e. This has the right ratio to give a better top speed of 109mph. It’s also much stronger because it has a 7” crown gear instead of a 6" one. The internals are being upgraded to make it even stronger and we are gettoing the arms welded up to strengthen them too. It will be refitted with new poly bushes.

[/quote]

Considering how much totally new ground is being covered in this project the detail in your planning is amazing. Nobody can come up with a question you haven’t already answered. Even where there is some doubt about whether something will work out quite as hoped there is a plan B.

Amazing job so far and the most interesting build thread ever. ![]()

![]()

![]()

![]()

![]()

The fun job has started this week of re-wiring the car from scratch. As an electrical and electronic engineer, I love this stuff though ![]() Creating a wiring diagram to explain it all, with cable thicknesses and cable paths chosen optimally for reliability and reduced weight. I’m using some components specifically to reduce weight too and sometimes I’m swapping out old ones, just to make the installation easier, e.g. the twin horns.

Creating a wiring diagram to explain it all, with cable thicknesses and cable paths chosen optimally for reliability and reduced weight. I’m using some components specifically to reduce weight too and sometimes I’m swapping out old ones, just to make the installation easier, e.g. the twin horns.

I designed and fabricated the wiring loom for my Fisher Fury R1 from scratch too and never had a single electrical issue, through good design practice and ensuring every connection is crimped, soldered and insulated well. No two wires of the same colour run alongside each other, to massively simplify diagnostics and testing too.

New twin horns that fit in the allocated space a lot better.

Modern electronic flasher unit to ensure indicators and hazards flash as fixed rate regardless of load.

We are fitting a pedestrian alarm to let people know we are there, without resorting to the very loud horns (which are a bit aggressive). It has it’s own switch on the dash with custom logo.

The whole MX-5e re-wiring project is being documented on the OSSEV website as we go along.

Before we refit the pop-up headlights, we are refurbishing them a little bit. The frames are good, as are the sealed halogen units but, the bowls and retainers needed cleaning up and repainting. We are re-using the old halogen 50W/50W sealed units for now and also fitting new H4 bulb connectors and uprated wiring to allow higher power bulbs + new lamps to be used later.

We could upgrade to LED but it just isn’t worth it to us. The headlights get used so infrequently and the beam patterns from all the LED headlights I’ve seen are not so good. They can make MOT/IVA tests a lot harder.

My new favorite thread, can’t wait to see the finished machine, come on - hurry up !

The Wipac crystal headlights are a very worthwhile upgrade. The beam pattern is created by the reflector and the lens is totally smooth. They look so much more impressive than the sealed beams even if they aren’t turned on. I used them on both of my NAs with Ring Zenon Ultima bulbs and they are amazing. Standard wattage but much more light output and a perfect beam pattern. Might find them cheaper on a Land Rover sales site.